Aug 28 2007

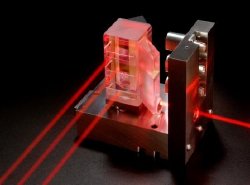

Agilent Technologies Inc. today announced its Complex Monolithic Optics (CMO) Development Program for OEM customers. The program offers customers the opportunity to incorporate the latest high-precision optics design technology into their optical system designs. CMOs are stand-alone optical assemblies that are created when multiple discrete optics are bonded together into a single, pre-aligned optical structure.

Optics have become ubiquitous and critical components for many applications, embedded in systems ranging from manufacturing equipment and scientific instrumentation to imaging and display, medical and aerospace/defense, and nanotechnology.

Agilent developed CMOs to address the needs of demanding interferometry applications where system stability and minimal downtime are critical. Traditionally, CMOs have been thought of as a high-end solution. Agilent’s CMO Development Program makes CMO design accessible for a wide variety of new applications where the overall cost of ownership is a key consideration. CMOs streamline an optical system by reducing the individual part count and improving performance and reliability. The result is reduced overall cost of ownership, size and weight.

Now, based on multiple CMO designs and thousands of units already deployed, Agilent is taking the lead in offering CMO solutions for an expanding number of industrial and commercial applications. Agilent’s CMO Development Program invites customers to engage with its Precision Optics group to take advantage of years of experience producing CMOs.

“The future of cost-effective optical system design will depend on smaller, lighter, more reliable optical assemblies,” said Vince Barich, Agilent Precision Optics operations manager. “The very nature of a CMO lowers the cost of ownership because system installation becomes easier and downtime caused by alignment or contamination issues is greatly reduced or even eliminated.”

Typically, optical systems have been built using discrete optics that are individually mounted and manually aligned in optomechanical assemblies that were originally designed for scientific applications. While these work well in a laboratory setup, where technicians can maintain alignment and adjust for environmental factors, they are not ideal for commercial implementations that require reliable performance and long-term system stability. CMOs are the next step in the evolution of optical system design, replacing bulky assemblies with a single, smaller, more efficient and cost-effective optic.

Agilent’s CMO Development Program connects customers with Agilent’s optical scientists and engineers plus its in-house production team to develop a CMO-based solution. The development of a new CMO begins with an assessment of the customer’s system needs and a determination of where a CMO can offer value. The design review process is closely coupled with Agilent’s fabrication and coating team for seamless design to production. Precision CMO designs, incorporating proprietary optical fabrication techniques, thin-film coating expertise and sub-surface damage control, are created using deterministic manufacturing controls and verified with precision metrology.