European researchers have developed a cost-effective method for manufacturing flexible displays in much the same way that newspapers are printed. Their work promises to revolutionise packaging, advertising and even clothing.

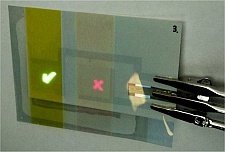

OLEDs on packaging, foir example, could show if it has been tampered with. Source: ROLLED

OLEDs on packaging, foir example, could show if it has been tampered with. Source: ROLLED

Ultra-thin and energy efficient displays that use organic compounds to emit light have been stirring up excitement in the consumer electronics industry for several years. Organic Light Emitting Diodes (OLEDs) are already being used commercially in some high-end flat-screen televisions, offering superior image quality, wider viewing angles and lighter power consumption than the current generation of Liquid Cristal Display (LCD) and plasma flat-panel TVs. But OLEDs’ unique properties mean the displays using them can be put to a far wider range of uses, from electronic paper to adaptive clothing – so long as production costs can be brought down.

“Lowering production costs is extremely important if OLED devices are to become more widespread, and particularly if they are not just going to be restricted to high-end applications,” explains Arto Maaninen, technical manager of the printed electronics department of the VTT Technical Research Centre in Finland.

Maaninen led the team of researchers behind the EU-funded ROLLED project, which developed a technique for manufacturing OLED devices at considerably lower cost than current methods.

Whereas the OLEDs now making their way into TV sets and some mobile devices are manufactured in a glass substrate, the ROLLED researchers print their OLEDs onto flexible protective films, a procedure known as roll-to-roll processing that allows thousands of devices to be rapidly and cost-effectively produced in a single “print run.”

As part of their work, the researchers developed printable nano-particle indium tin oxide (ITO) coatings to form the anode, and they developed a new low-work function metal cathode, with the light-emitting organic layer sandwiched in between.

As an electric current passes from the anode to the cathode layer, the organic compound emits light that, depending on the application, can create a high-contrast TV image or a simple coloured sign. Each OLED sheet is just a fifth of a millimetre thick – equivalent to three or four sheets of paper.

“The biggest cost saving is on equipment. The equipment needed to print OLED displays is widely available, so the initial manufacturing costs are lower compared to other techniques. The material costs are about the same, but you can produce many more units in a much shorter period of time,” Maaninen says. “This brings down overall production costs three to five fold.”

Organic light everywhere

That opens the door to OLEDs finding their way into all manner of everyday items. The biggest of several markets for cheap, flexible OLED displays may be in product packaging. Sheets of them could, for example, be used to create more visible logos and more attractive promotional wrappings to differentiate products on supermarket shelves, or they could be used as part of “smart packaging” to improve product quality and safety.

“One demonstrator we developed consists of a two-colour OLED display: one showing a green tick, the other a red cross. It could be used on packaging to let consumers know if a product has been opened or tampered with,” the ROLLED coordinator says.

The tiny amount of energy OLED devices need to operate mean they could be powered by a small watch battery, solar cells or even radio waves. “It might be possible for a store to use its shelves as an RFID antenna that would power the OLEDs in the product packaging,” Maaninen says.

The project team developed on that concept – an extension of Near Field Communication (NFC) – in another demonstrator that consisted of a simple business card showing the EU flag. A single-coloured OLED lit up the stars of the flag if a mobile phone with an RFID transmitter was placed near it.

Using flexible OLED displays in smart product packaging or even to replace paper billboard advertisements still remains some way off, however, as too does the vision of clothing embedded with OLEDs to display different messages, pictures or colours.

“Our flexible OLED devices could be used in clothes – the biggest barrier would be making them robust enough to survive being worn and put through a washing machine,” Maaninen says.

Having developed the technical ability to produce flexible OLEDs roll to roll, the ROLLED project partners are now working to meet the needs and requirements of potential end applications. Their aim is to carry out the first market trials within the next two years.

ROLLED received funding under the ICT strand of the EU’s Sixth Framework Programme for research.