Machine vision has spread rapidly in the inspection of agri-food commodities, including meat, fish, and particularly the automatic inspection of fruits and vegetables. More accurate than human inspectors, machine vision systems can scan food for a variety of unique characteristics, such as its ripeness, size, shape, and color, as well as to detect the presence of blemishes, stems, seeds or dirt. Besides exerting influence on a product's appearance, these characteristics measure its nutritional content and suitability for preservation.

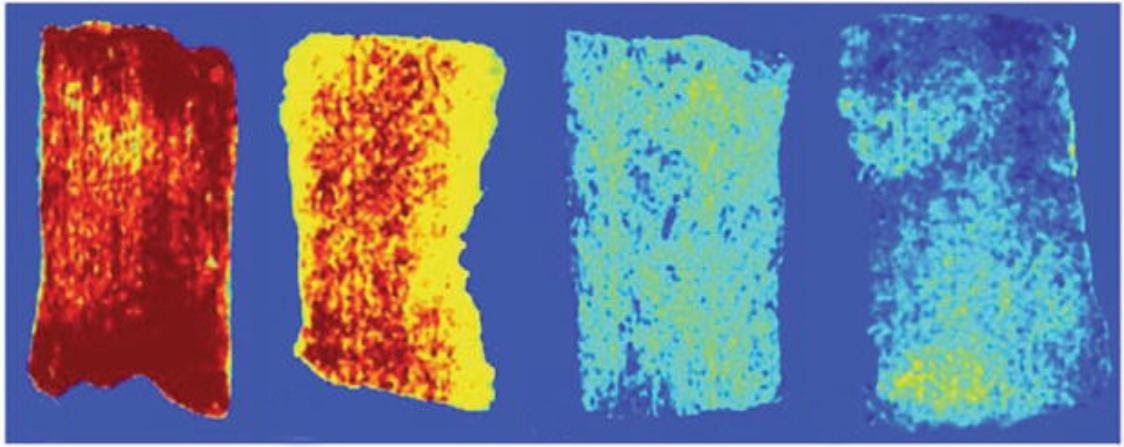

Hyperspectral detection of E. coli contamination on fish. Image Credit: InTechOpen

Hyperspectral detection of E. coli contamination on fish. Image Credit: InTechOpen

While food inspection systems have long relied on RGB color sensors, there is a push to incorporate hyperspectral cameras operating in the ultraviolet, visible, and infrared spectral ranges. Hyperspectral cameras provide more detailed information, making them particularly well-suited for the classification of blended raw materials and the detection of contaminants. They can also quantify a product's chemical composition, for instance, its levels of pH, sugar, fat, water, and salt content.

While hyperspectral imaging opens new opportunities, its addition to a machine vision system significantly increases the amount of data transmitted from the camera to the host PC. Overloading data transmission beyond what the network can handle results in latency delays and dropped data packets. Latency introduces the potential for the system to inadvertently allow damaged or contaminated products down the conveyor belt by not keeping up with inspection processing. Contaminated food can ruin a producer's hard-earned brand reputation, underscoring the importance of ensuring quality at every step in the value chain. More seriously, contaminated foods may cause Salmonella, E. coli or other health issues when eaten.

Frame Grabbers Ensure Safer Processing

In most cases, the bandwidth-heavy processing of additional spectral bands captured by hyperspectral cameras mandates the use of a powerful frame grabber. Applying a frame grabber also lets the system designer to move the host PC far away from a conveyor line, a step that saves space and shields the host PC from dust, vibration and humidity.

In these imaging environments, systems designers are increasingly adopting frame grabbers built on the high-speed CoaXPress® interface. CoaXPress or "CXP" is an open and royalty-free asymmetric, high-speed, point-to-point serial communication standard.

CoaXPress is now available in two versions: CXP-6 with a top end of 6.2 Gbps per channel and the newer CXP-12 standard delivering 12.5 Gbps per channel, scalable to 50 Gbps when four channels are used to support a single camera with zero latency. Along with high throughput, CXP enables the safe use of cable lengths up to 100 meters, far further than GigE Vision or Camera Link interfaces. It also enables the reliable transmission of data, communication, control and power (Power-over-CoaXPress) to be transmitted over a single coax cable for cost-effective, hassle free cable management.

BitFlow, Inc. is one the original innovators in CoaXPress frame grabbers. Having released its first CXP frame grabber, the Karbon-CXP, back in 2012, BitFlow has remained on the cutting edge with a string of introductions that have set the pace for the machine vision industry. Today, it offers the Cyton CXP and Claxon CXP families of CoaXPress in multiple designs to meet the needs of critical high-speed inspection tasks utilizing area scan or linescan cameras.

BitFlow's latest development is the new Claxon Fiber frame grabber based on CoaXPress over Fiber (CoF) interface technology. This PCIe Gen3 x8 CXPoF board is configured with a single port for QSFP+ hot-swappable, parallel fiber-optical/copper transceiver modules. Besides increased bandwidth and immunity to electromagnetic interference, an important benefit of transmitting data over fiber is that it provides the flexibility of running multi-mode fiber cable up to 150 meters (492 feet) between cameras and the PC. On single-mode fiber cables the maximum increases to 40 kilometers (24 miles) without needing complex, expensive repeaters.