Sometimes total darkness is necessary to view clearly. Black paint coating devices can reduce stray light, improving images and performance for astronomy and precision optics, because every detail counts for the most sophisticated telescopes and optical systems, so their manufacturers search for the darkest black materials to coat them with.

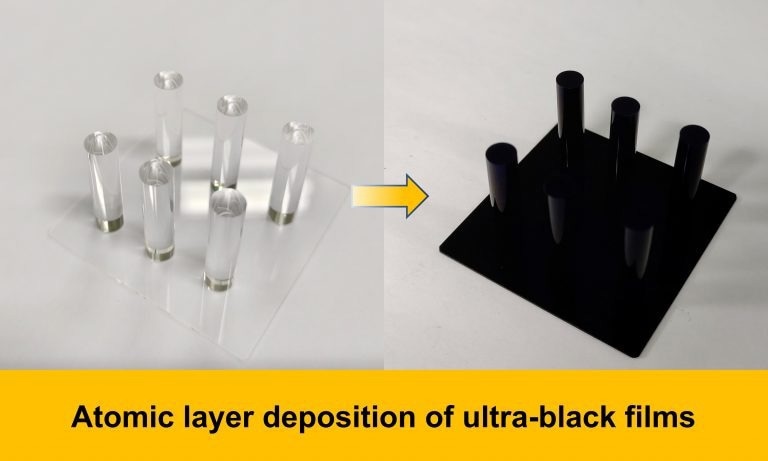

The team’s ultrablack coating can be applied to curved surfaces and magnesium alloys to trap nearly all light. Image Credit: Jin, J., et al.

The team’s ultrablack coating can be applied to curved surfaces and magnesium alloys to trap nearly all light. Image Credit: Jin, J., et al.

Researchers from the University of Shanghai for Science and Technology and the Chinese Academy of Sciences have developed an ultrablack thin-film coating for aerospace-grade magnesium alloys, which is published in the Journal of Vacuum Science & Technology A by AIP Publishing. Their coating is strong enough to withstand harsh environments while still absorbing 99.3% of light.

Current coatings are frequently insufficient for optical equipment used in harsh environments or for telescopes operating in space vacuum.

Existing black coatings like vertically aligned carbon nanotubes or black silicon are limited by fragility, and it is also difficult for many other coating methods to apply coatings inside a tube or on other complicated structures. This is important for their application in optical devices as they often have significant curvature or intricate shapes.

Yunzhen Cao, Study Author, Chinese Academy of Sciences

The researchers used atomic layer deposition (ALD) to solve these issues. Using this vacuum-based manufacturing method, a target is put inside a vacuum chamber and exposed to different kinds of gas one at a time. The gases stick to the object's surface in thin layers.

One big advantage of the ALD method lies in its excellent step-coverage ability, which means we can obtain uniform film coverage on very complex surfaces, such as cylinders, pillars, and trenches.

Yunzhen Cao, Study Author, Chinese Academy of Sciences

The researchers used alternating layers of silicon nitride (SiO2) and titanium carbide (TiAlC) doped with aluminum to create their ultrablack coating. Together, the two materials stop almost all light from reflecting off the coated surface.

TiAlC acted as an absorbing layer, and SiO2 was employed to create an anti-reflection structure, and as a result, nearly all of the incident light is trapped in the multilayer film, achieving efficient light absorption.

Yunzhen Cao, Study Author, Chinese Academy of Sciences

The researchers tested a broad range of light wavelengths, from violet light at 400 nm to near infrared at 1,000 nm, and discovered an average absorption of 99.3%. They even applied their coating to magnesium alloys, which are frequently used in aerospace applications but are prone to corrosion, using a unique barrier layer.

Cao said, “What is more, the film shows superb stability in adverse environments, and is tough enough to withstand friction, heat, damp conditions, and extreme temperature changes.”

The authors are working to further improve the performance of their coating in the hopes that it will be used to improve optical hardware and space telescopes that are subjected to the harshest conditions.

Cao said, “Now that the film can absorb over 99.3% of incoming visible light, we are hoping to expand its light absorption range even further to include ultraviolet and infrared regions.”

Journal Reference:

Jin, J., et al. (2024) Robust ultrablack film deposited on large-curvature magnesium alloy by atomic layer deposition. Journal of Vacuum Science & Technology A. doi.org/10.1116/6.0003305.