Counterfeiting is considered a serious issue that causes an impact on an extensive range of industries ranging from medicine to electronics. This can cause immense economic losses, thereby resulting in safety concerns and causing a risk to health.

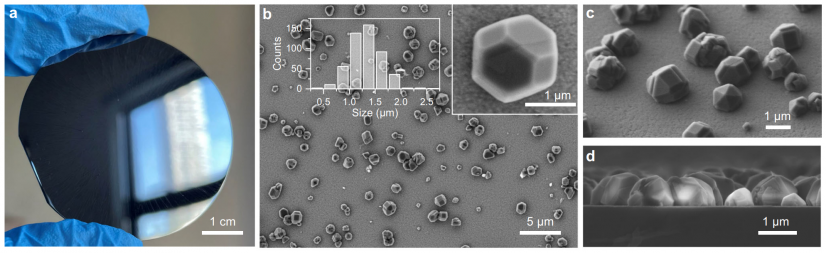

Photo of the diamond PUF label (a). Electron microscopy images of a diamond-based PUF-label, individual diamond microparticles and their spread on the silicon substrate are clearly visible: top-view (b), side-view. (c) cross-section (d). Image Credit: The University of Hong Kong

Counterfeiters and anti-counterfeiters have been locked in a technological arms race. Despite anti-counterfeiting tools turning out to be increasingly high-tech—such as thermochromic ink, holograms, and radio frequency identification tags- fake products are becoming extremely hard to differentiate from genuine articles since counterfeiters are using increasingly advanced technology.

Recently, a research group headed by Dr. Zhiqin Chu of the Department of Electrical and Electronic Engineering of the University of Hong Kong (HKU), with Professor Lei Shao of the School of Electronics and Information Technology of Sun Yat-sen University, and Professor Qi Wang from Dongguan Institute of Opto-Electronics of Peking University, came up with a pioneering technological solution.

Dr. Chu’s team has made diamond-based anti-counterfeiting labels, identified in the industry as PUFs-Physically Unclonable Functions.

The research group made such labels by planting small artificial diamonds, called diamond microparticles, on a silicon plate using a method known as Chemical Vapor Deposition (CVD).

The diamond microparticles, all varying in shape and size, develop a special pattern when they scatter on the silicon substrate. It is impossible to replicate this pattern, and thus it uniquely scatters light. In other words, it develops a special “fingerprint” that could be scanned using a phone.

The second level of individuality, and thus security, is available from the fact that such diamond microparticles have defects called silicon-vacancy (SiV) centers.

SiVs offer diamond microparticles a special optical property—they discharge near-infrared photoluminescence when a green light is shone on them, making them easily recognizable.

Furthermore, such special optic signatures could be integrated and digitized into codes of very high security and sophistication that can be read by an easy smartphone scanner and/or a confocal fluorescence microscope.

Very significantly, such diamond-based labels are highly ideal for use in commercial products as they are extremely hard—in the trials they resisted heat, the action of physical damage, and chemicals.

Also, they are inexpensive—it costs around just one US dollar to make 10,000 such labels of 200 µm × 200 µm dimensions. Furthermore, because they are made from diamonds, such anti-copying labels would improve the product’s value.

The labels are all set to be utilized commercially, stated Dr. Chu, adding the fact the team’s next step is “to focus on the practical applications.”

Diamond anti-counterfeiting will be favored in various high-end products such as jewelry, luxury goods, electronic products, and automobiles.

Dr. Zhiqin Chu, Department of Electrical and Electronic Engineering, University of Hong Kong

Journal Reference

Zhang, T., et al. (2023) Multimodal dynamic and unclonable anti-counterfeiting using robust diamond microparticles on heterogeneous substrate. Nature Communications. doi.org/10.1038/s41467-023-38178-1