There are currently 439 nuclear reactors in operation in 32 countries around the world, including Taiwan. Nuclear energy now generates about 10% of the world's electricity and is the second largest source of low-carbon power, producing 28% of the total in 2019. Yet nuclear power is not without its hazards as the world learned in the accidents at Fukushima, Japan (2011), Goiania, Brazil (1987), Chornobyl, Ukraine (1986), and Three Mile Island, Pennsylvania (1979).

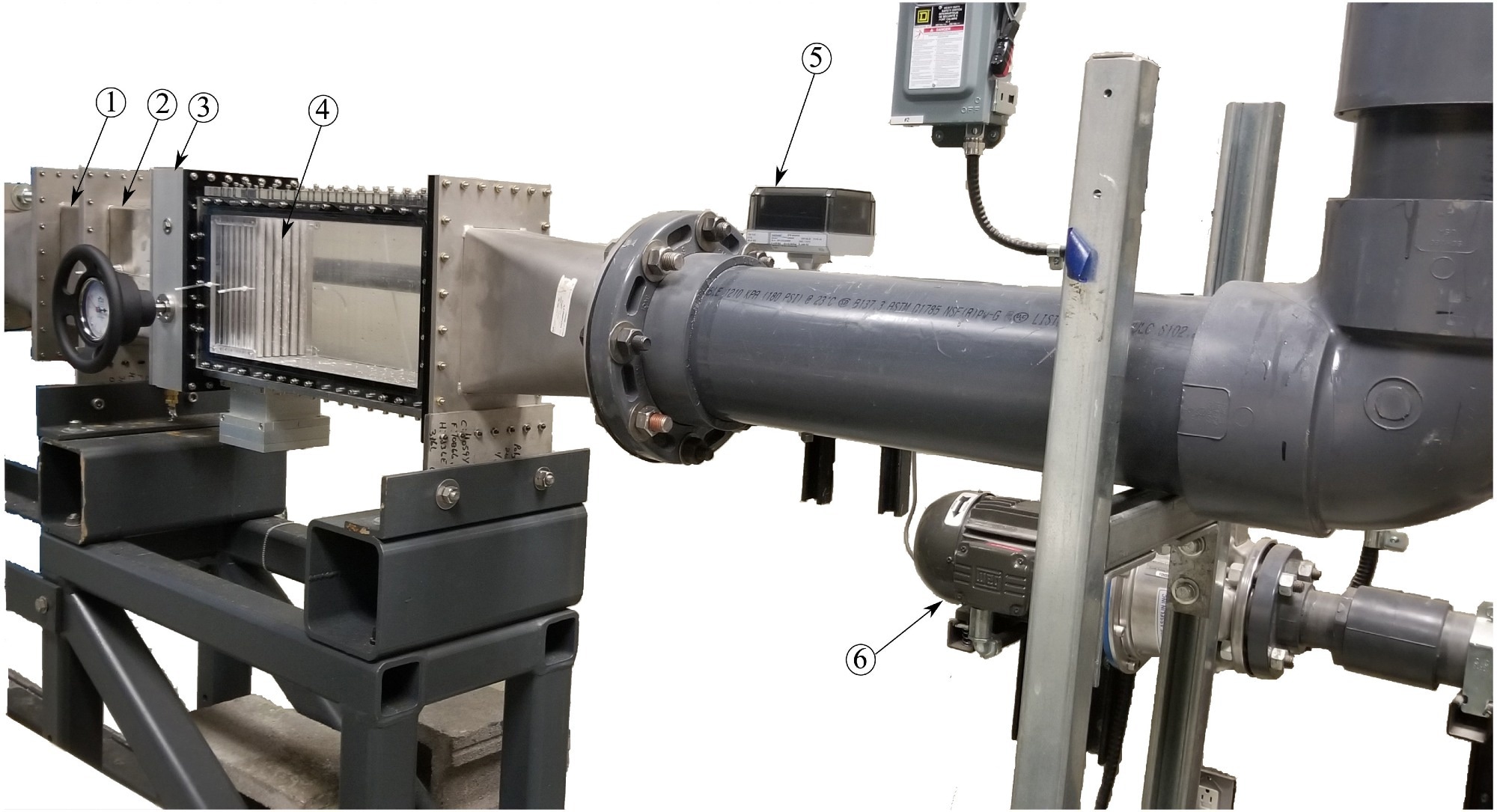

The main components of the test set-up are: (1) flow straightener, (2) barrel–baffle chamber, (3) displacement jet flow mechanism, (4) rod bundle, (5) water flow meter (6) centrifugal pump. Image Credit: Polytechnique Montréal

The main components of the test set-up are: (1) flow straightener, (2) barrel–baffle chamber, (3) displacement jet flow mechanism, (4) rod bundle, (5) water flow meter (6) centrifugal pump. Image Credit: Polytechnique Montréal

The Danger of Fuel Rod Bundle Vibration

The flow-induced vibration of fuel rods in nuclear reactors has become a concern for engineers and regulators who strive to ensure that safety is not compromised during a plant loss-of-coolant accident (LOCA). One fail-safe process used during LOCA incidents is to discharge built-up pressure in the barrel–baffle region through holes and slots where it will flow inside the core. Flow emanating from LOCA holes and slots serves to equalize the pressure across the baffle plate. In some incidents, however, jet crossflow-induced vibration can cause grid-to-rod-fretting (GTRF) in the fuel assemblies due to their proximity to the LOCA holes. In extreme cases, the fuel rods may undergo fluid-elastic instability resulting in violent and destructive vibrations, leading to abrasive wear to the rod cladding.

Scientists at the Department of Mechanical Engineering, Polytechnique Montréal, (Montreal, QC) recently performed a study on how the jet flow injected through LOCA holes and slots can induce GTRF. Analysis of this type can play a key role in setting safety margins for the operating conditions of reactors. Their experiments emulated the jet crossflow-induced vibration of fuel rods by performing fluid-elastic instability (FEI) tests on flexible rod bundles. The effect, which is called ”stand-off distance,” was observed in a tested bundle of 36 rods in a 6 x 6 pattern.

An experimental facility was set up in the Department of Mechanical Engineering at Polytechnique Montréal. All fabricated test components were assembled on a sturdy structure to eliminate any extraneous vibrations. A 2 HP centrifugal pump was used to pump water through the test section. Before the flow entered the tested rod bundle, it first passed through a flow straightener to minimize any turbulence from pipe fittings. The flow then went into the barrel–baffle chamber. In the jet displacement mechanism, the uniform flow was converted into a jet flow through a nozzle to be injected into the flexible rod bundle.

Using a Mikrotron MotionBLITZ Cube GigE CMOS camera set on top of the testing unit, sequential images of the rod bundle response were captured as the rods were excited by the jet crossflow at changing velocities. The Mikrotron camera was set at 1000 frames per second (fps) while recording at 1280 x 1024 pixel resolution, a frame size large enough to capture all 36 rods in the bundle. At 1000 fps, the camera’s maximum full-resolution recording time is 3.24 seconds. However, it can record for longer time durations at reduced resolution and lower imaging speeds.

An image processing algorithm was developed in MATLAB to detect and thus track the center of each of the 36 rods in a raw image series to obtain the rod bundle vibration at each of the jet flow velocities.

The experimental results for the stream-wise vibrations showed that jet eccentricity significantly affects the dynamical behavior of the rod array. The longer-term objective of this research is to determine the stability threshold for fluid-elastic instability in fuel assemblies in proximity to LOCA holes that may occur during operation, therefore enhancing the longevity and safety of the fuel rods.