The EU-funded LAMpAS project has successfully developed the first laser system, based on Interference Patterning combined with a polygon scanner system, for high-throughput, low-cost surface production with controlled topographic characteristics. This new concept of laser machine can produce well-defined surface patterns with controlled length scales and feature sizes in order to provide surfaces with advanced functions.

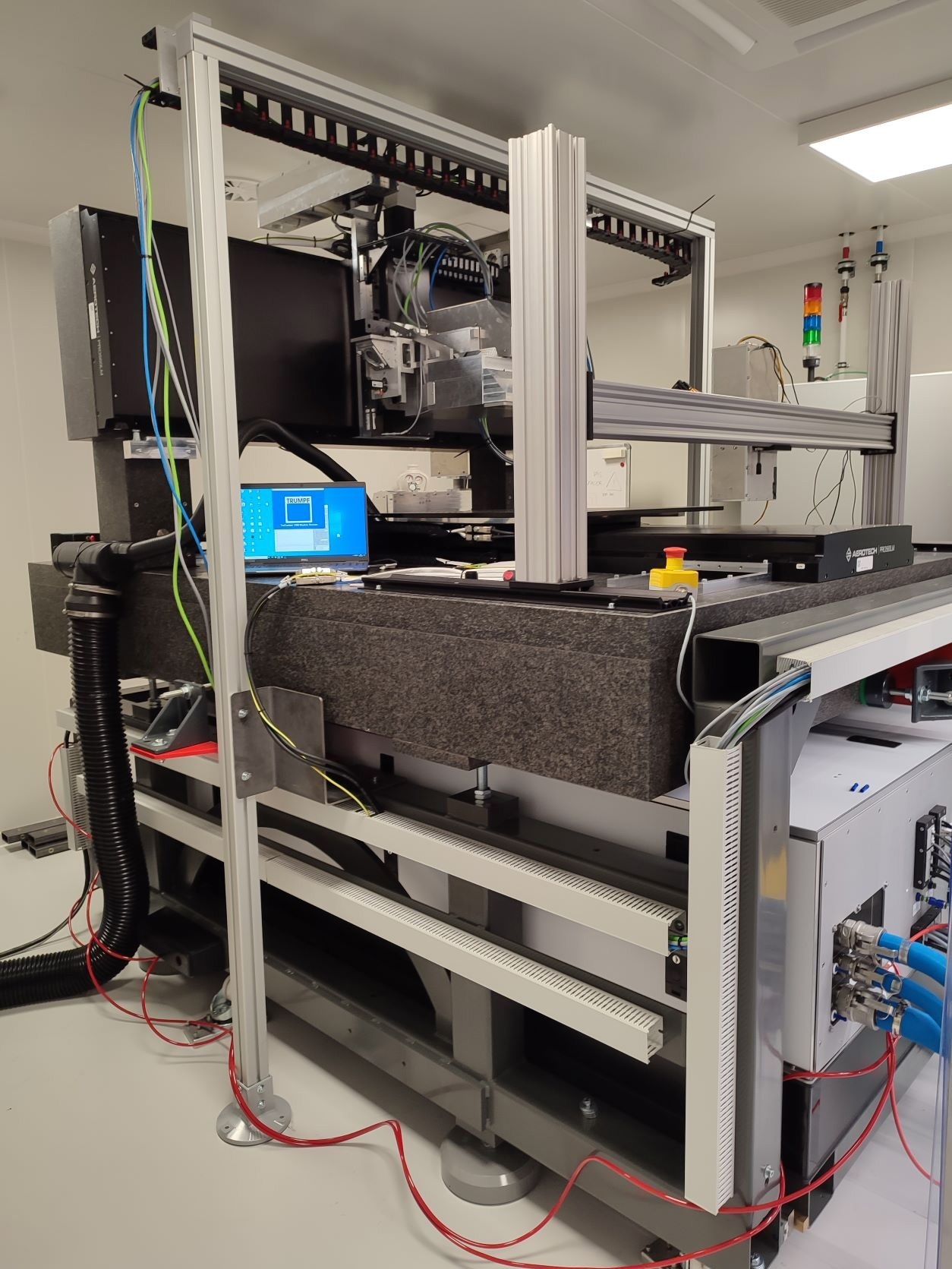

Image Credit: LAMpAS

The new laser machine consists of several important modules, including:

High-power ps-laser source: a 1.5 kW laser system has been developed (by TRUMPF), with 1-3 ps pulse durations and a reduced spectral bandwidth required for Direct Laser Interference Patterning. The laser source can provide pulse energies up to 4 mJ, making it ideal for this application.

Advanced laser surface texturing optics: for the first time worldwide, a unique optical head was constructed, which combines of a specially designed polygon scanner (Scanlab) with a Direct Laser Interference Patterning unit (TU Dresden). The module allows the fabrication of periodic textures at high throughput, producing hierarchical patterns for surface functionalization.

Real-time surface characterization module: two real-time monitoring systems were developed in LAMpAS, which are based from one side on a near-infrared camera as well as based camera system, which can monitor the structuring process in real time. Furthermore, they can detect heat-accumulation or indirectly predict in real-time the depth of produced topographies with resolution of about 15 nm.

The machine will significantly increase the potential of laser structuring to design functionalized surfaces by enhancing the efficiency, flexibility, and productivity of the process. Thanks to that, it will be possible to reach different characteristics of the surfaces, such as decorative finishes, easy-to-clean properties, anti-fingerprint properties, or anti-calc properties, without using paint or other more expensive technology.