For the progress of energy science, in situ observation and recording of significant liquid-phase electrochemical reactions in energy devices are considered to be vital.

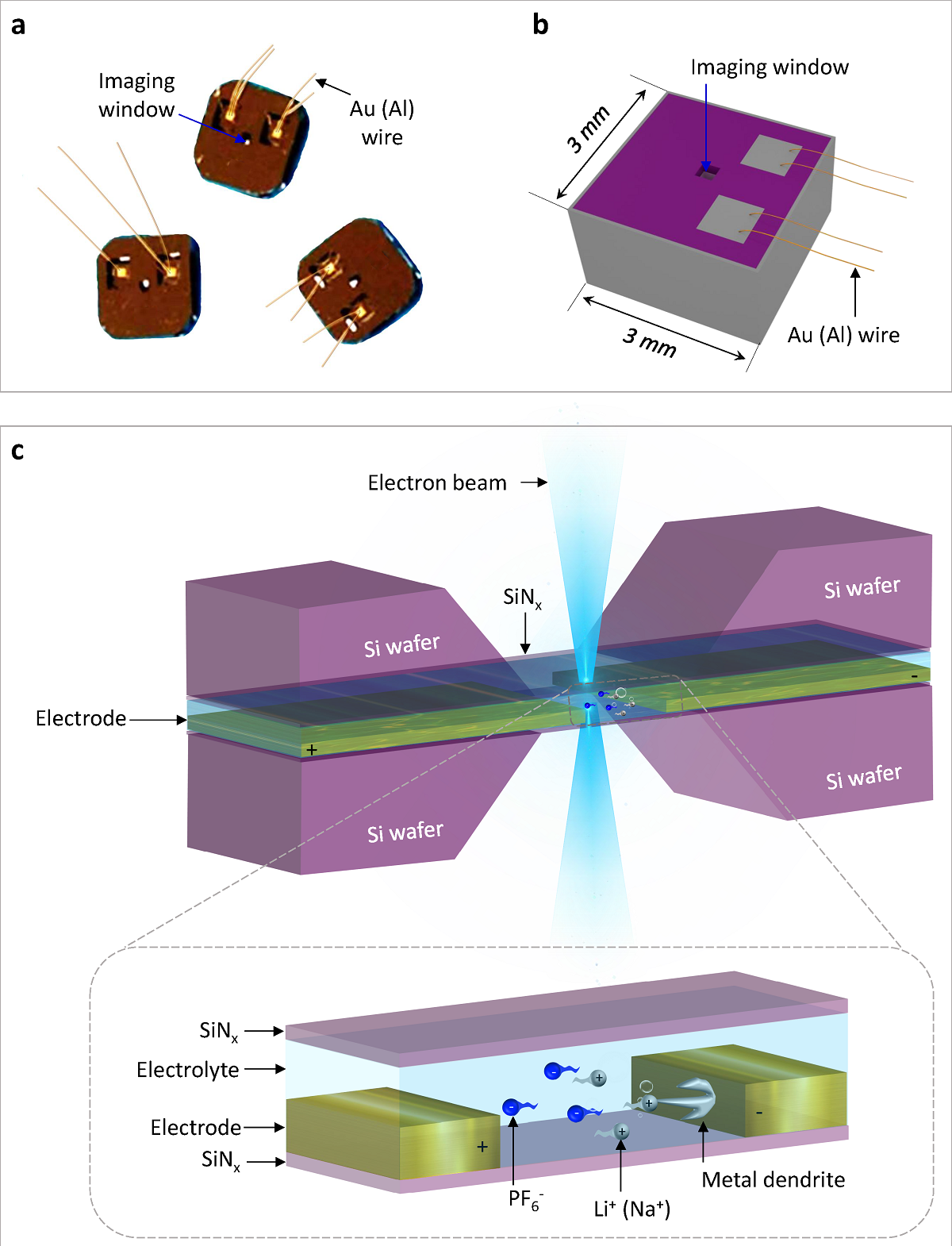

Schematic illustration of the electrochemical liquid cell. Image Credit: Image Credit: © Yang, R. et al

Recently, a research group headed by a scholar from the City University of Hong Kong (CityU) came up with a novel device to maintain liquid specimens for transmission electron microscopy (TEM) observation. This sets the stage for directly visualizing and recording complicated electrochemical reactions at the nanoscale in real time at high resolution.

The research group hopes that this groundbreaking technique will offer insights into strategies for fabricating a strong research tool for disclosing the secrets of electrochemical processes in the future.

The use of traditional TEM is restricted to stable, thin, and solid samples due to the vacuum environment (a vacuum environment avoids the electrons from being absorbed or deflected together with their pathways and impacting observation) in the chamber for keeping the specimens.

Liquid specimens are vacuum-inconsistent, so they could not be directly probed in conventional TEM. Luckily, with the advent of the highly progressed in-situ “liquid cell TEM,” it is possible to learn about liquid phase dynamic processes in situ, like noting electrochemical reactions in energy devices, crystal nucleation and growth in solution, and the life activities of living cells.

The so-called “liquid cell” is a main component of TEM to maintain the specimens for the electron beam to pass through, thus allowing in-situ observation.

However, it is difficult to manufacture a high-quality liquid cell for TEM since it involves integrating electrodes and encapsulating electrolytes in a small “closed” liquid cell to avoid leakage and link it to an external power source simultaneously.

A research group co-headed by Dr. Zeng Zhiyuan, Assistant Professor in the Department of Materials Science and Engineering at CityU, and Professor Li Ju from the Massachusetts Institute of Technology (MIT), successfully came up with an effective and novel technique to fabricate “closed” electrochemical liquid cells, which can highly enhance the resolution of TEM with liquid samples.

The newly developed closed liquid cell performs two main jobs: (1) enclosing the liquid samples in a closed container, thereby separating them from the microscope vacuum environment; and (2) confining the liquid samples to a thin enough liquid layer using two electron-transparent silicon nitride (SiNx) windows, so that electrons can travel through the liquid layer and image the reactions.

Dr. Zeng Zhiyuan, Assistant Professor, Department of Materials Science and Engineering, City University of Hong Kong

For the high-performance “closed” electrochemical liquid cells in this protocol, the research team made use of sophisticated nanofabrication methods, such as photolithography, to fabricate the core component of in situ liquid TEM—the liquid cell.

Photolithography is a process that makes use of ultraviolet light to shift a geometric design from an optical mask to a light-sensitive chemical (photoresist) coated on the substrate.

The research group fabricated the bottom chip and top chip separately and assembled them collectively. Titanium or gold electrodes were deposited on the bottom chip at the time of the metal deposition process. Then the electrolyte was made to load and sealed within the liquid cell.

Using this innovative liquid cell with the transmission electron microscope, the dynamic electrochemical reactions of the liquid sample on the electrode surface can be recorded in real-time at high resolution through the TEM operating system incorporated with a high spatiotemporal resolution camera.

The electrochemical liquid cell designed by our customized nanofabrication method has thinner SiNx imaging windows (35 nm) than commercial ones (50 nm). It also has a thinner liquid layer (150 nm) than that of commercial ones (1,000 nm).

Dr. Zeng Zhiyuan, Assistant Professor, Department of Materials Science and Engineering, City University of Hong Kong

Zhiyuan added, “The thinner SiNx imaging windows and thinner liquid layer ensure that our fabricated liquid cell can capture electrochemical reactions with better TEM spatial resolution than commercial ones can.”

The team hopes that a lot of applications for the in-situ TEM observation of electrochemical reactions will arise soon following the progress of the electrochemical liquid cell with the selection of patterned metal electrodes and the encapsulated liquid electrolytes in the liquid cell.

Also, this newly suggested fabrication protocol can be used in other in-situ methods beyond TEM. For instance, a proper adjustment to this protocol would be ideal for the fabrication of electrochemical liquid cells for in-situ X-Ray characterizations of electrochemical reactions (X-Ray diffraction, X-ray absorption spectroscopy, etc.).

The corresponding authors of the study are Dr. Zeng, from CityU, and Professor Li, from MIT. The first author is Mr. Yang Ruijie, from Dr. Zeng’s research group. The other collaborators are from Xiamen University and Xi’an Jiaotong University.

The study was financially supported by the Hong Kong Research Grants Council and the Shenzhen Science and Technology Innovation Committee.

Fabrication process of the electrochemical liquid cell

In situ TEM observation of electrochemical processes and post-in situ characterizations. Video Credit: © Yang, R. et al.

Journal Reference:

Yang, R., et al. (2022) Fabrication of liquid cell for in situ transmission electron microscopy of electrochemical processes. Nature Protocols. doi.org/10.1038/s41596-022-00762-y.