A new electrode material has been developed by researchers from Tokyo Metropolitan University. This material is used in deep-ultraviolet (DUV) light-emitting diode applications.

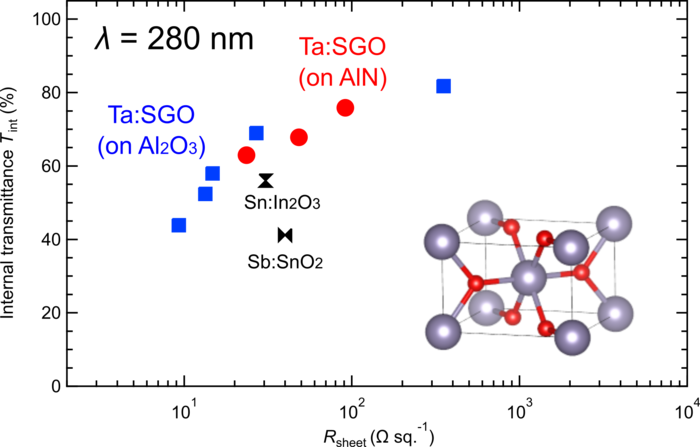

The newly developed Ta:SGO films on aluminum oxide and aluminum nitride are shown to have higher transmittance for deep UV light than common transparent electrode materials like indium tin oxide and antimony tin oxide, as well as comparably low resistivity. Image Credit: Tokyo Metropolitan University.

The newly developed Ta:SGO films on aluminum oxide and aluminum nitride are shown to have higher transmittance for deep UV light than common transparent electrode materials like indium tin oxide and antimony tin oxide, as well as comparably low resistivity. Image Credit: Tokyo Metropolitan University.

The researchers made use of a state-of-the-art deposition method to develop thin films of an alloy of germanium oxide and tin oxide with added tantalum—discovering that they display outstanding unparalleled transparency and electrical conductivity for DUV light. The newly developed electrodes can impact the industry, as similar wavelengths are utilized for the manufacture of microchips and sterilization processes.

Deep ultraviolet (DUV) light has a few highly significant roles to play in industry and society. It has a wavelength ranging from 200 to 300 nm and could also be utilized to sterilize water and surfaces by disabling viruses and bacteria and cure adhesives that get stiffened on exposure to DUV light. Importantly, it is utilized in the manufacture of the majority of advanced semiconducting devices and chips.

With the DUV technology adoption only becoming larger, researchers are eager to come up with deep UV light-emitting diode (LED) devices, tapping the peerless scalability, compactness, and energy efficiency of LED sources. LEDs exhibit light-emitting layers of the material fitted between a pair of transparent electrodes, which have to permit the light through as well as conduct electricity.

Although these LEDs are present, the electrode materials available currently are yet to integrate conductivity with improved transparency; they still tend to absorb a considerable proportion of DUV light.

Currently, a research group headed by Professor Yasushi Hirose of Tokyo Metropolitan University has come up with a thin film transparent electrode exhibiting outstanding conductivity and, most importantly, unparalleled transparency for deep UV light.

The researchers integrated an extensively utilized ingredient of transparent electrodes, tin oxide, and blended it with germanium oxide—a material with an identical crystalline structure but improved transparency.

Generally, these two materials are not soluble in each other, so the team made use of the pulsed laser deposition. It is a technique that enables insoluble materials to be deposited collectively without them impulsively isolating into different regions.

Also, they displayed that deep UV transmittance (the proportion of light allow in) kept constantly improving with more germanium oxide addition. By adding a few tantalum, the electrical conductivity of the films was enhanced.

By improving the recipe, the generated films displayed a low resistivity and few of the best transmittance of DUV light out of all recognized electrode materials. This consists of the most general transparent electrode material, indium tin oxide (ITO).

Essentially, they displayed that the films could be developed on aluminum nitride (AlN) substrates by making use of a crystalline “seed” layer of tin oxide.

Aluminum nitride is a chief material present in deep UV LEDs; the compatibility of the newly designed tantalum tin germanium oxide (Ta:SGO) films of the group with AlN makes their work highly hopeful for real-world applications in the next generation of light sources for chip manufacture, and beyond.

This study was financially supported by Grant Number JPNP20004 from the New Energy and Industrial Technology Development Organization (NEDO).

Journal Reference:

Nagashima, Y., et al. (2022) Deep Ultraviolet Transparent Electrode: Ta-Doped Rutile Sn1–xGexO2. Chemistry of Materials. doi.org/10.1021/acs.chemmater.2c01758.