Reviewed by Emily Henderson, B.Sc.Nov 11 2022

Astronomers today aim to observe the faintest and farthest objects. The newest facilities for doing this are Extremely Large Telescopes (ELTs), which have apertures in the range of several dozen meters. But increasing the size of telescopes is just one aspect of the problem.

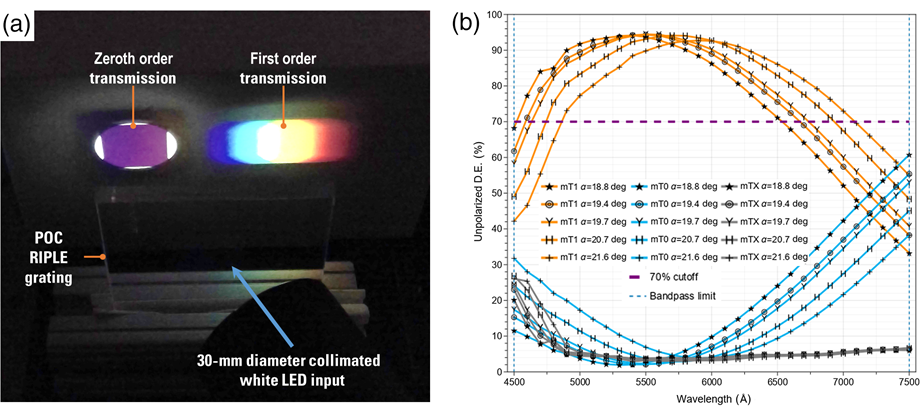

Visual demonstration of the performance of the diffraction grating. The zeroth order transmission refers to light that goes straight through the grating without undergoing diffraction (which should be minimized), whereas the first order transmission refers to the first diffraction peak for each frequency of light. (b) Diffraction efficiency of the gratings for first order transmission (orange) and zeroth order transmission (cyan). Worth noting, the first order diffraction efficiency of the grating was over 70% for a wide wavelength range spanning more than 200 nm. Image Credit: The Authors.

Visual demonstration of the performance of the diffraction grating. The zeroth order transmission refers to light that goes straight through the grating without undergoing diffraction (which should be minimized), whereas the first order transmission refers to the first diffraction peak for each frequency of light. (b) Diffraction efficiency of the gratings for first order transmission (orange) and zeroth order transmission (cyan). Worth noting, the first order diffraction efficiency of the grating was over 70% for a wide wavelength range spanning more than 200 nm. Image Credit: The Authors.

The ability to detect the gathered photons as effectively as possible makes up the other component. Making all other optical parts of astronomical instruments more effective is crucial at this point. A diffraction grating is a key tool in modern astronomical science.

Similar to how a glass prism does, its function is to spatially spread incoming light into its frequencies. Diffraction gratings can separate light of various wavelengths with the extremely high resolution because of a carefully designed structure that takes advantage of the fact that photons behave like waves.

Gratings enable researchers to examine the spectral characteristics of celestial bodies when used in conjunction with a telescope and spectrometer.

Researchers Menelaos K. Poutous of the University of North Carolina at Charlotte and Hanshin Lee of the University of Texas at Austin focused on a completely different method of fabricating diffraction gratings as a result of the somewhat stagnant advancement made in grating technology over the past ten years.

Reactive ion-plasma etching (RIPLE), a plasma-based manufacturing technique typically used for semiconductors, was successful in producing proof-of-concept high-efficiency diffraction gratings, as reported in their paper that was recently published in the Journal of Astronomical Telescopes, Instruments, and Systems.

Simply put, the RIPLE method applied in this study involves “drawing” the desired grating pattern onto a chrome masking layer atop a quartz substrate using a high-precision electron beam.

Chemically reactive plasma is then used to carve the grating pattern directly onto the quartz substrate; the chrome mask serves as a shield and the plasma only damages the exposed areas.

The process’ various parameters were fine-tuned by the researchers using simulations, theoretical calculations, and experimental trial and error. As a result, they were able to create first-order diffraction gratings with extremely accurate nano-scale structures.

This resulted in an unpolarized diffraction efficiency that was nearly theoretical, peaking at 94.3% and remaining above 70% over a wavelength range longer than 200 nm.

This type of performance has been only rarely achieved in diffraction gratings used for astronomy, where every bit of efficiency gain really matters due to photon starvation.

Hanshin Lee, Research Scientist, College of Natural Sciences, University of Texas at Austin

The fact that the grating structure is integrated directly into the glass substrate, meaning that they share the same material properties, is another benefit of creating diffraction gratings using the RIPLE process.

Our gratings can be very robust optically, thermally, and mechanically, which makes them ideal for harsh environments, such as those found in space observatories and cryogenic systems. This allows for their application in a broad range of scientific and engineering spectroscopic measurements.

Menelaos K. Poutous, Associate Professor, Interdisciplinary Optics, Department of Physics and Optical Science, University of North Carolina at Charlotte

Overall, the study’s findings show how the RIPLE process has the potential to completely change how diffraction gratings are made. In the upcoming era of ground-based ELTs with apertures over 30 m, the researchers are upbeat about the use of such high-efficiency gratings.

Hopefully, these gratings will help astronomers observe incredibly faint objects far away in space in the years to come.

Journal Reference:

Lee, H., et al. (2022) Reactive ion plasma etched surface relief gratings for low/medium/high resolution spectroscopy in astronomy. the Journal of Astronomical Telescopes, Instruments, and Systems. doi:10.1117/1.JATIS.8.4.045002.