A recent study conducted at the GEP research platform and published in Expert Systems with Applications investigated the effects of dust accumulation on the reflectivity parameter of optical mirrors.

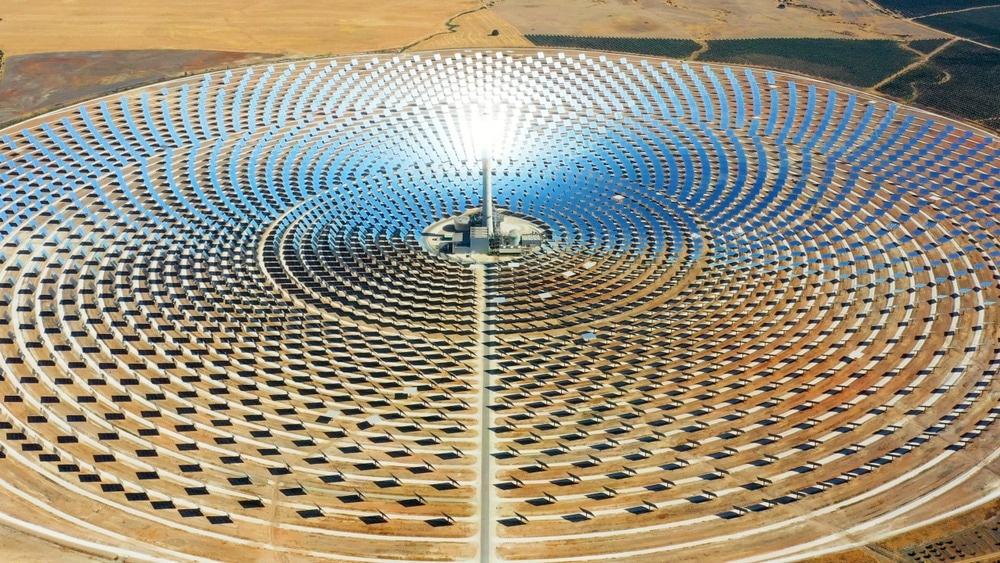

Study: Dust InSMS: Intelligent Soiling Measurement System for dust detection on solar mirrors using computer vision methods. Image Credit: Fly_and_Dive/Shutterstock.com

A new system for dust detection was proposed based on the data collected. The proposed system was based on a classification method using convolutional neural networks and image processing algorithms. This method has not previously been used to quantify the soiling phenomenon on concentrating solar power (CSP) mirrors.

The accumulation of dust has a significant impact on the optical characteristics of solar plants, particularly the reflectance of solar mirrors. Minimizing the effects of reflectivity losses from soiling and improving the cleaning technique are crucial for enhancing the properties of solar mirrors.

Effect of Harsh Climate Conditions and Dust Accumulation on CSP Plants

Most solar initiatives have been established in the sun-rich regions of North Africa, the Middle East, the United States, India, and China. Extreme weather conditions, such as dust storms, high levels of airborne, and settled particle environments, are typical of these geographical locations.

As a result, the majority of locations for CSP plants are in dry or semi-arid regions, where they contend with not only the harsh temperature but also a lack of water resources, which restricts the methods for cleaning and restoration. The optical effectiveness of solar concentrators, particularly the reflectivity of solar mirrors, is impacted by soiling and dust accumulation.

The dust particles that have accumulated on the mirrors' surface deviate and have an impact on the amount of solar energy collected. The particles absorb some energy, and some of it is reflected without the proper focus. The reflectivity losses due to the soiling phenomenon significantly negatively impact optical efficiency and overall productivity CSP plant.

Impact of Soiling on the Optical Efficiency of CSP Plant

The effect of soiling on optical effectiveness and the total productivity of the solar plant has been investigated by several researchers. Researchers have recently studied the effects of soling on both PV and CSP technologies, taking into account the decline in reflectance and transmittance of mirror and glass samples. The soiling drop for samples of mirrors can be as high as 35%, while it could be as low as 12% for glass samples.

Some investigations compare the impact of soiling simultaneously for both PV and CSP under the same circumstances. The soiling rates for CSP and PV can be varied from 8 to 14%.

Strategies to Improve the Cleaning Process for the Soiling Phenomenon

The cleaning procedure, which removes dust particles and lowers reflectivity loss, is the best way to reduce the soiling condition. Cleaning expenses make up a sizable amount of all O&M expenses. Improving cleaning frequency and approach lowers the costs associated with O&M. A good cleaning plan ensures a balance between cleaning expenses and productivity losses.

Including a basic solar plant cleaning schedule and excluding the soiling distribution throughout the solar field cleaning processes can be improved. Since solar collectors are not affected by the same quantity of dust, direct measurements using soiling sensors can introduce a more detailed plan for the cleaning process.

Limitations of Current Sensors

There are numerous restrictions on measuring the reflectance of solar mirrors and calculating the soiling problem with current sensors that are either time or money-related. High-accuracy spectrometers are only helpful in laboratories and cannot be utilized in working environments.

The reflectometers are portable and suited for on-site testing, but they take a lot of time and require multiple measurements to quantify soiling on a mirror. Evaluating several mirrors is a highly challenging and time-consuming task. The TraCS sensor is a stationary instrument that can monitor soiling continually is expansive.

Development of an Easier and Faster Method for Direct Soiling Measurement

El Ydrissi et al. suggested a more straightforward and quicker dust InSMS system for measuring the direct loss of reflectance or soiling of CSP mirrors. The proposed system was based on a classification method using convolutional neural networks and image processing algorithms. This system can estimate the reflectivity parameter in addition to the amount of dust that has formed on the mirror surface and the cleaning cycle, which shows how much of the mirror is exposed to the solar field following the most recent cleaning.

The primary benefits of this approach are the speed of measurements and the ease of configurations when estimating the reflectivity of mirrors using RGB photographs as opposed to using many measurement points and then using their average. The suggested sensor further employs the GPS coordinates of each measurement to find the shortest cleaning path and comprehend the distribution of soiling on the solar field.

Research Findings

An innovative system to assess the impact of dust accumulation on solar reflectors was introduced in this research. Instead of using multiple measurement locations and then averaging them, the key benefits of the suggested system are the speed of measurements and the simplicity of setups. It estimates the reflectance of mirrors using only one RGB image. No comparable study in the literature employs the same strategy to quantify the soiling phenomenon on CSP mirrors as this method, which is based on the classification approach using the CNN model and image processing algorithms. The test loss and accuracy of the suggested model are 0.28 and 0.96, respectively.

These results can be further enhanced by expanding the dataset used to train this model and enhancing the pre-processing applied. More advancements can be introduced to increase the accuracy and features of the proposed system, such as expanding the dataset, experimenting with more intricate CNN models, and utilizing IoT technologies. IoT technology transforms Dust InSMS measurements from sporadic measurements to ongoing, real-time monitoring. It also enables connectivity between other sensors that can use the soiling parameter, such as a cleaning robot that can process cleanings automatically.

Reference

El Ydrissi, M., Ghennioui, H., Ghali Bennouna, E., Alae, A., Abraim, M., Taabane, I., & Farid, A. (2022). Dust InSMS: Intelligent Soiling Measurement System for dust detection on solar mirrors using computer vision methods. Expert Systems with Applications, 118646. https://www.sciencedirect.com/science/article/pii/S095741742201689X

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.