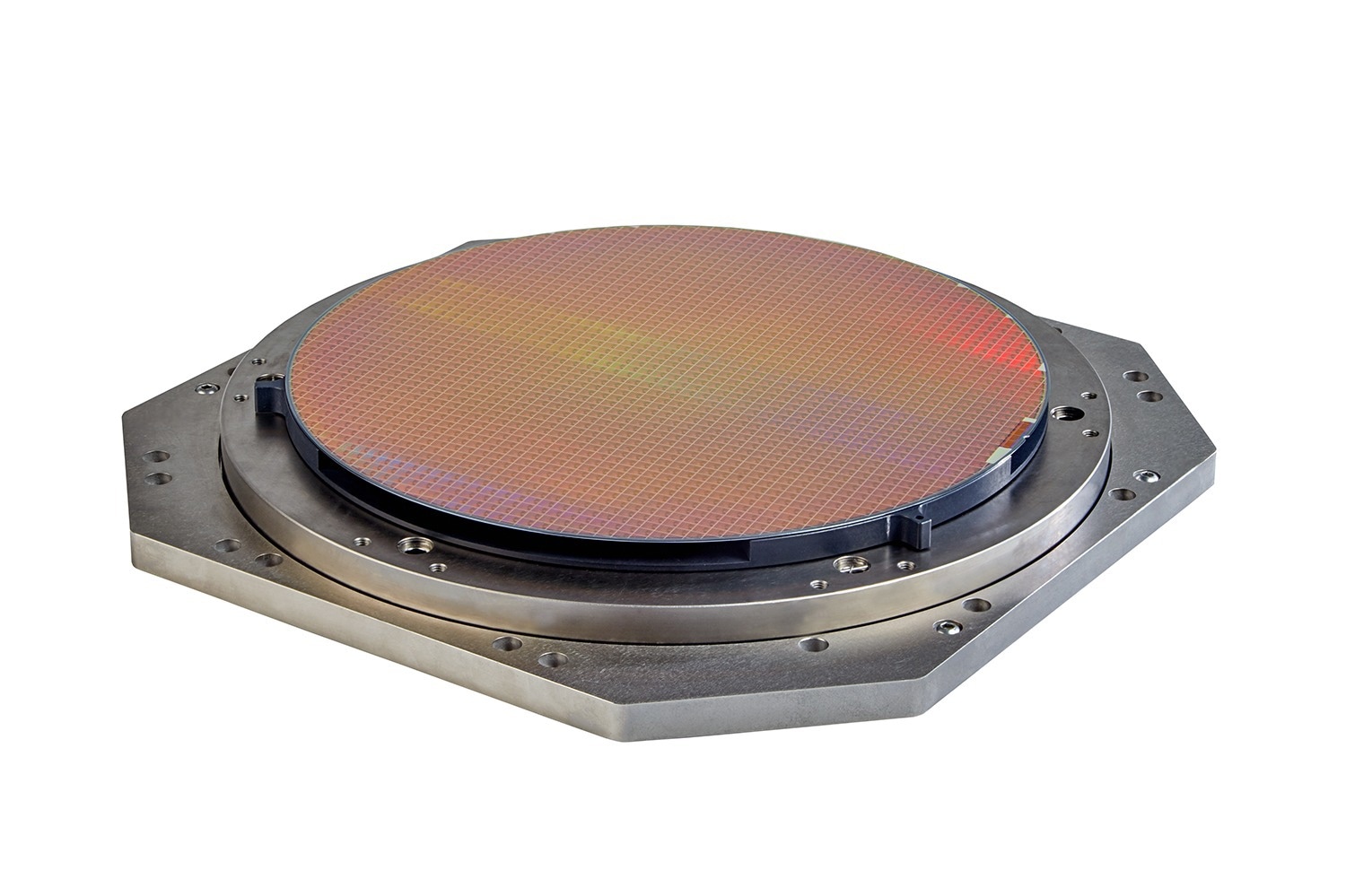

Queensgate, a brand of Prior Scientific, today announced the launch of the WP-Z-120A Wafer Stage. Millisecond response times and high bandwidth make the WP-Z-120A wafer positioning system ideal for applications where high throughput is essential. The Wafer Stage can be used in wafer inspection with an optical microscope such as the Prior Scientific OpenStand microscope or an OEM version using various optical or other inspection techniques.

Image Credit: Queensgate

The stage is designed to hold 300 mm (12") wafers and delivers an exceptional performance with a load capacity of up to 8 kg, suitable for even very heavy wafer chucks. The stage incorporates capacitive positioning sensors to provide nanometer displacement measurement and precision closed-loop feedback. Flexure guidance offers friction-free, reliable motion to more than 120 µm in closed-loop mode and achieves fast response and settle times with Queensgate’s digital closed-loop controllers.

“We are pleased to introduce WP-Z-120A Wafer Scanner to the market. We wanted to design a wafer scanner that can carry a high load but achieves market-leading fast response and settle times. The Wafer Scanner was designed with OEM customers in mind and can be adapted to new custom versions easily.”

Alison Raby, Business Development Manager for Queensgate

WP-Z-120A Wafer Stage can be customized for different environments and specifications. It is vacuum (HV) compatible and ideal for a chamber in an electron microscope. Ultra-high vacuum (UHV) and UHV-RAD radiation-hard versions are also available. A higher load custom version can be used for up to 14 kg loads and a tip-tilt version for platform leveling and scanning is available. An extended range of 160 μm and a smaller size for 200 mm wafers are possible upon request.

About Queensgate, a brand of Prior Scientific

Queensgate, a brand of Prior Scientific, has over 40 years of experience providing custom and OEM nanopositioning solutions where precision, accuracy, and dynamic performance are required. Queensgate offers market-leading performance due to enhanced control technology. Many of Queensgate’s products are used in demanding environments such as ultra-high vacuum, high throughput manufacturing, and space equipment.

Over half of the world’s hard disks are tested using Queensgate’s ultra precision stages. Queensgate is based in Cambridge in the UK with manufacturing facilities in Paignton UK and regional operations in the US, Germany, China and Japan.