Holographic interferometry is a method for using light to measure stress, strain, and vibration. It determines defects in structural bonds by measuring the light’s wavelength. It fully utilizes a hologram’s capacity to mimic an object’s optical field of reflection or transmission.

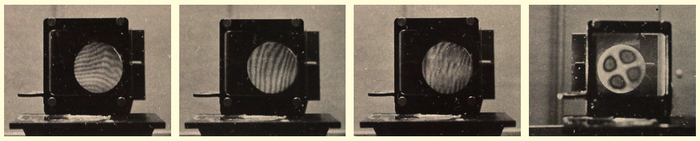

The last two images show the object’s vibration as seen in real-time and as a hologram reconstruction. Image Credit: Karl A. Stetson

The last two images show the object’s vibration as seen in real-time and as a hologram reconstruction. Image Credit: Karl A. Stetson

Two unanticipated properties of a hologram are used in holographic interferometry. In order for them to interfere with its reconstructed field, incoherent fields can be recorded by a hologram and coherently reconstructed. Secondly, a hologram can recreate an object’s optical field. When moved from its original location, it can be recreated with such accuracy that it interferes with the object’s original field.

Karl Stetson of Karl Stetson Associates described the invention of holographic interferometry, covered its development, and listed some of its most important applications in a review article that was published in Light: Advanced Manufacturing.

The paper, “The discovery of holographic interferometry, its development and applications,” evaluated the original tests and what might occur in the coming years.

Despite being greatly disappointed, the author was encouraged by Sean Johnston’s Holographic Visions: A History of New Science. Most of those experiments in the book’s descriptions underwent revision as a result of the author’s efforts. It enabled him to verify the theories and look at everything objectively.

The interference fringes on the borders of particular holographic reconstructions served as one illustration. In contrast to many decades earlier, the author described how his team collaborated to change their methods.

Researchers discovered that it was crucial to accurately determine how these fringes were created. The team thus found that it was particularly useful for real-time vibration monitoring on shiny surfaces.

For many sectors, it is essential to measure vibrations in real-time on reflecting surfaces. The team initially used tin cans and other straightforward forms, but they were unable to identify a field where holographic interferometry could be used to its full potential. However, the airline industry swiftly joined in with the help of acoustics professors.

Holographic testing came at a high initial cost and increased the price of products significantly. Airlines would invest in this as any failure would increase the cost beyond the initial investment.

Jet engines vibrate a great deal, and high cycle fatigue is a significant cause of the blades’ failure. They are built to have resonances that are not triggered by the operation’s rotational speeds. Holography provided a method to see the mode shapes and validate mathematical calculations.

The small space between the blade tips and the engine shell is what gives jet engines great efficiency. The engine casings are coated with an abrasion-resistant substance. The rotating blades will just scrape some material away and not fall off if they come into contact with the casing due to any deformation.

The scraping blades may knock off any areas where the seal is not firmly connected to the shell, which would reduce engine performance. During a holographic examination of a casing segment, ultrasonic noise exhibits disbanded regions as black spots.

Given the technological advancements over the last thirty years, the switch to digital holographic interferometry was unavoidable. There will undoubtedly be further advancements in this area in the future, but the author is unsure of where they will go.

Journal Reference:

Stetson, K. A., et al. (2022) The discovery of holographic interferometry, its development and applications. Light: Advanced Manufacturing. doi.org/10.37188/lam.2022.002.