Researchers have developed a novel compact camera that uses a variety of metalenses — flat nano-patterned surfaces used to modulate light — to capture high-quality wide-angle photos.

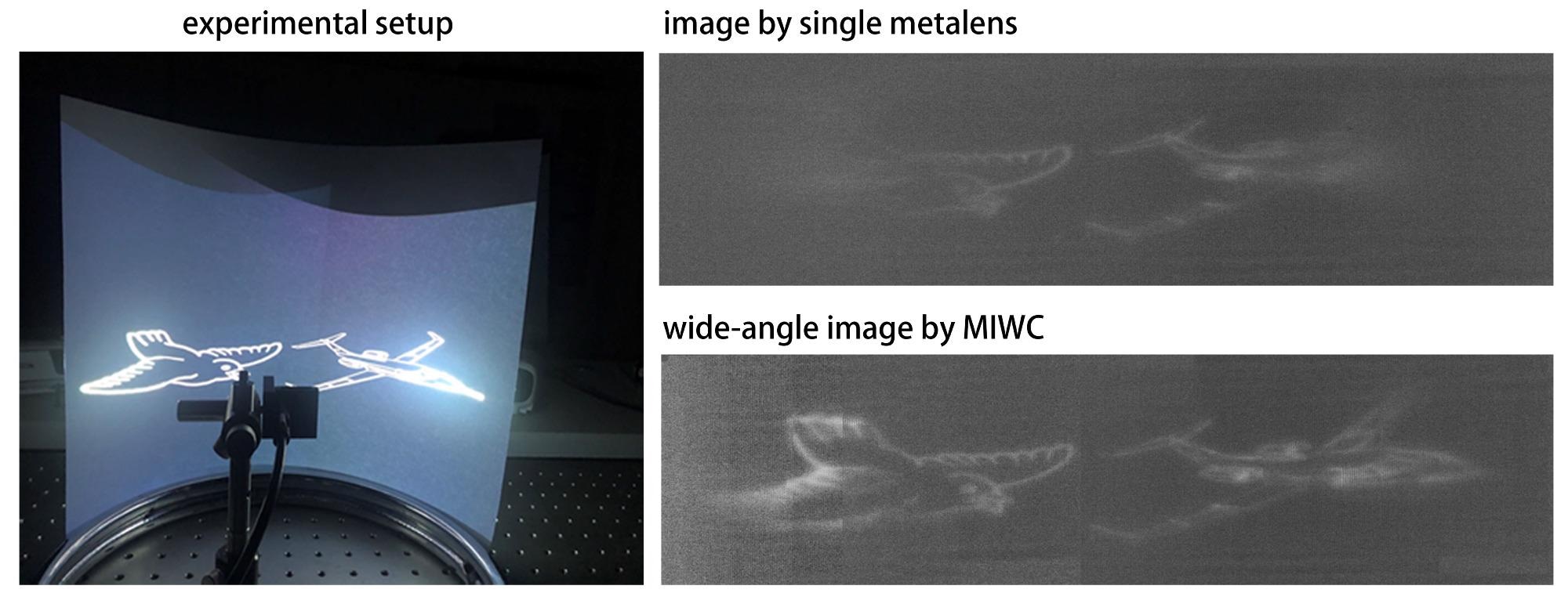

Researchers designed a new compact camera that acquires high-quality wide-angle images using an array of metalenses. Their new planar camera (MIWC) produced clearer images of pictures projected across a curved screen compared to a camera based on a single traditional metalens. Image Credit: Tao Li, Nanjing University.

Researchers designed a new compact camera that acquires high-quality wide-angle images using an array of metalenses. Their new planar camera (MIWC) produced clearer images of pictures projected across a curved screen compared to a camera based on a single traditional metalens. Image Credit: Tao Li, Nanjing University.

The novel technique could allow wide-angle cameras to be included in smartphones and portable imaging equipment for vehicles such as cars or drones by removing the bulky and heavy lenses currently required for this type of photography.

In Optica, the Optica Publishing Group’s journal for high-impact research, Tao Li and colleagues from Nanjing University in China describe their new ultrathin camera. With a viewing angle of more than 120°, the latest camera, which is only 0.3 cm thick, can capture clear photographs of a scene.

Wide-angle photography is effective for capturing vast amounts of data and producing gorgeous, high-quality photos. Wide-angle photography can improve performance and reliability in machine vision applications like autonomous driving and drone-based surveillance, for instance, by displaying impediments users cannot normally see while backing up a vehicle.

To create an extremely compact wide-angle camera, we used an array of metalenses that each capture certain parts of the wide-angle scene. The images are then stitched together to create a wide-angle image without any degradation in image quality.

Tao Li, Researcher, Nanjing University

Miniaturizing the Wide-Angle Lens

A fish-eye compound lens or another type of multilayer lens is typically used for wide-angle imaging. While researchers have attempted to develop wide-angle cameras using metalenses in the past, they have had poor image quality or other problems.

The researchers employed a variety of metalenses in their current study, each of which was meticulously built to focus on a diverse range of illumination angles. This enables each lens to photograph a portion of a wide-angle item or scene accurately. To construct the final image, the clearest elements of each image can be computationally patched together.

Thanks to the flexible design of the metasurfaces, the focusing and imaging performance of each lens can be optimized independently. This gives rise to a high-quality final wide-angle image after a stitching process. What’s more, the array can be manufactured using just one layer of material, which helps keep the cost down.

Tao Li, Researcher, Nanjing University

Seeing More with Flat Lenses

The researchers employed nanofabrication to make a metalens array and placed it directly on a CMOS sensor to illustrate the novel method, resulting in a planar camera that measured roughly 1 cm × 1 cm × 0.3 cm.

Researchers then utilized this camera to photograph a wide-angle scene made by lighting a curved screen encircling the camera at a distance of 15 cm with two projectors.

While picturing the words “Nanjing University” displayed across the curved screen, they contrasted their innovative planar camera to one based on a single standard metalens. The planar camera created an image that clearly showed every word and had a viewing angle of more than 120°, which was more than three times that of a standard metalens camera.

The planar camera utilized in this study included separate metalenses that were only 0.3 mm in diameter, according to the researchers. To improve the camera’s imaging quality, researchers want to grow these to around 1 to 5 mm. The array could be mass-produced after optimization to lower the cost of each unit.

Journal Reference:

Chen, J., et al. (2022) Planar wide-angle-imaging camera enabled by metalens array. Optica. doi.org/10.1364/OPTICA.446063.