One difficulty in 3D printing silica optical fibers is extending previous findings of small-scale glass “bulk or slice” print from very few millimeters to centimeters. However, recently performed experiments with 3D printing of silica glasses and silica optical fiber have proven successful.

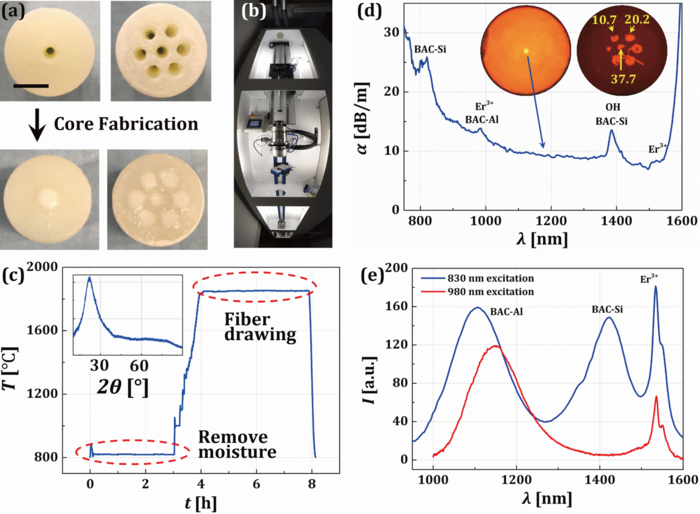

(a) Images of the 3D printed preforms and subsequently filled cores; (b) Optical fiber drawing tower used in this experiment; (c) Temperature change of the fiber drawing process; (d) Loss spectrum of the 3D printed single-core, and loss of seven cores fibers at 632.8 nm; (e) Emission spectra of a single core fiber excited by the 830 nm and 980 nm lasers. Image Credit: Yushi Chu, Xinghu Fu, Yanhua Luo, John Canning, Jiaying Wang, Jing Ren, Jianzhong Zhang, and Gang-Ding Peng.

(a) Images of the 3D printed preforms and subsequently filled cores; (b) Optical fiber drawing tower used in this experiment; (c) Temperature change of the fiber drawing process; (d) Loss spectrum of the 3D printed single-core, and loss of seven cores fibers at 632.8 nm; (e) Emission spectra of a single core fiber excited by the 830 nm and 980 nm lasers. Image Credit: Yushi Chu, Xinghu Fu, Yanhua Luo, John Canning, Jiaying Wang, Jing Ren, Jianzhong Zhang, and Gang-Ding Peng.

Dr. Yushi Chu and Prof. Jianzhong Zhang of Harbin Engineering University (HEU), along with Prof. Gang-Ding Peng of the University of New South Wales (UNSW) established a research group to broaden small-scale glass printing by several orders of magnitude. The study demonstrated that optical fiber preforms could be manufactured using 3D printing.

DLP 3D printing technology was used to successfully create a centimeter-scale optical fiber preform, and single-mode and multi-mode optical fibers were generated by changing the parameters during fiber drawing. Based on this foundation, the study team expanded their work by co-doping bismuth and erbium ions into single-core and seven-core fibers. Researchers were able to create multi-component fibers as well as structured fibers.

It is crucial to evaluate 3D printing technology’s capacity to construct complicated fiber structures. By lowering separation and integration procedures, the ability to show these additive capabilities benefited production processes.

Dopants from five various elements were also presented by the researchers. Bismuth, erbium, germanium, titanium and aluminum were among the elements used. Waveguides were constructed using germanium, titanium and aluminum, which enhanced the core glass network structure and made it more suitable for luminescence.

The scientists also studied fiber loss, which is considered the most significant feature that inhibits 3D printing optical fiber, as part of their research. Researchers noticed that increasing the fullness of the core and cladding had a positive effect. It also lowered the amount of moisture in the optical fiber, lowering fiber loss. During the manufacturing process, temperature and pressure may be precisely controlled to accomplish these results.

3D printing technology has the potential to transform specialty optical fibers, opening up new opportunities for such fibers in the future. The development of multicore fiber fan-in/fan-out or optimal mode couplings in space division multiplexing without optical fiber splicing will also be likely.

Journal Reference:

Chu, Y., et al. (2022) Additive Manufacturing Fiber Preforms for Structured Silica Fibers with Bismuth and Erbium Dopants. Light: Advanced Manufacturing. doi.org/10.37188/lam.2022.021.