Luxinar, a global leader in sealed CO2 laser sources, is delighted to be supporting its agent ASTC as it exhibits the manufacturer’s OEM 45iX and a selection of its SR series sealed CO2 laser sources on stand P820 at Laser & Photonics Taiwan in Taipei, taking place 15-18 December 2021.

Image Credit: Luxinar

Partnering with Luxinar

Luxinar’s sealed CO2 laser sources can be used on a wide array of materials including textiles, plastics, rubber, glass, wood, ceramics and metal to mention a few. Applications range from cutting, drilling, kiss-cutting and perforating to marking, engraving, scribing and welding. Its lasers are installed across many industries such as electronics, automotive, textiles, packaging, food and beverage.

Luxinar does not provide turnkey solutions, preferring instead to work with OEMs and machine builders who integrate Luxinar sealed CO2 laser sources to provide a complete laser solution to their customers. Most product ranges are available in three wavelengths; 10.6µm, 10.25µm and 9.3µm, allowing companies to design modular machines to meet their respective process parameters.

Laser & Photonics Taiwan is one of the highlights of our events calendar and we’re really excited that it is going ahead as an in-person exhibition.

Patrick Kim, Regional General Manager of Luxinar’s Korea office

Kim continues, “It’s the ideal opportunity to share our solutions and expertise directly with our customers, and for visitors to discuss the challenges they’re facing in today’s market. This will help us understand how we can support them in working to deliver increased levels of productivity and quality.”

Consistent High Precision of Electronic Devices

Lasers are now commonplace in the manufacture of electronics. The semiconductor industry continues to reduce the size of its dies and packaged devices, which is made possible because lasers process with high precision on a minimal heat-affected zone (HAZ). Although there are several laser options, CO2 lasers are often preferred due to the power/cost ratio and longer wavelengths, compared to other industrial laser types.

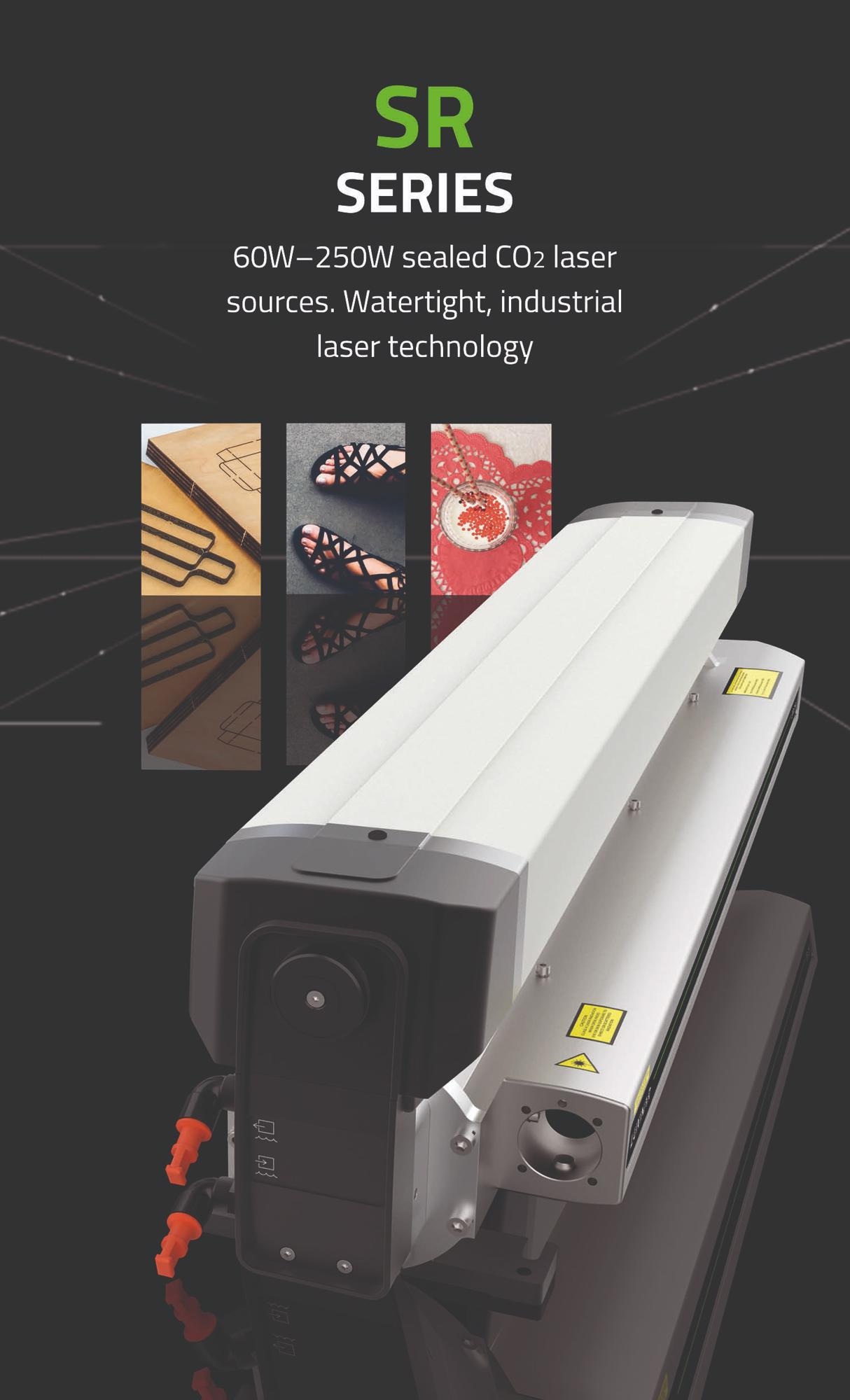

Luxinar’s SR series is targeted for customers who demand high quality, reliability and versatility from their laser. Applications include mobile phone covers, LCD glass processing, and microelectronics; attention is paid to every detail of the engineering process to guarantee minimal operating costs.

The CO2 laser source is hermetically sealed, with a rating of IP66, making it ideal for harsh environments as it gives protection against dust, humidity and water spray. Its compact, lightweight design consists of an integrated, field-replaceable RF power supply with enhanced diagnostics, and the option of a DC power supply.

Flexible and Consistent Repeatability in High- and Low-Tech Applications

Laser processing provides flexibility, with extremely accurate control of cut depth, high repeatability and consistency without the need to change tools, unlike the mechanical alternatives.

A best seller for Luxinar is the extremely versatile OEM 45iX laser source. It can be easily integrated into existing production lines, whether these are system concepts with scanners or other beam guidance components.

As with all products from Luxinar, the OEM 45iX has a high quality, round symmetrical beam for fast processing speeds and a short optical pulse with high peak power. This improves the edge quality and minimises HAZ. The technology is based on the well-proven slab principle, with no need for gas recirculation equipment such as vacuum pumps or pressure control systems. Maintenance and service costs are minimal resulting in a long lifetime and trouble-free operation for the OEM 45iX.

Try Before You Buy

For manufacturers uncertain as to whether a sealed CO2 laser can be used in, or to improve, a specific manufacturing process, Luxinar is able to assist by conducting sample tests at its in-house application laboratories. This service is available to any interested party, regardless of whether the client is an existing customer.

The laboratories are well equipped to conduct a range of processes. Sample turnaround times are rapid and include detailed complimentary application reports and advice from experienced application engineers.