Tomoscopy is an imaging technique that involves calculating three-dimensional images of the inside of a material in quick succession. A research team led by physicist Francisco García from Helmholtz-Zentrum Berlin has successfully made a world record at the TOMCAT beamline of the Swiss Light Source at the Paul Scherrer Institute.

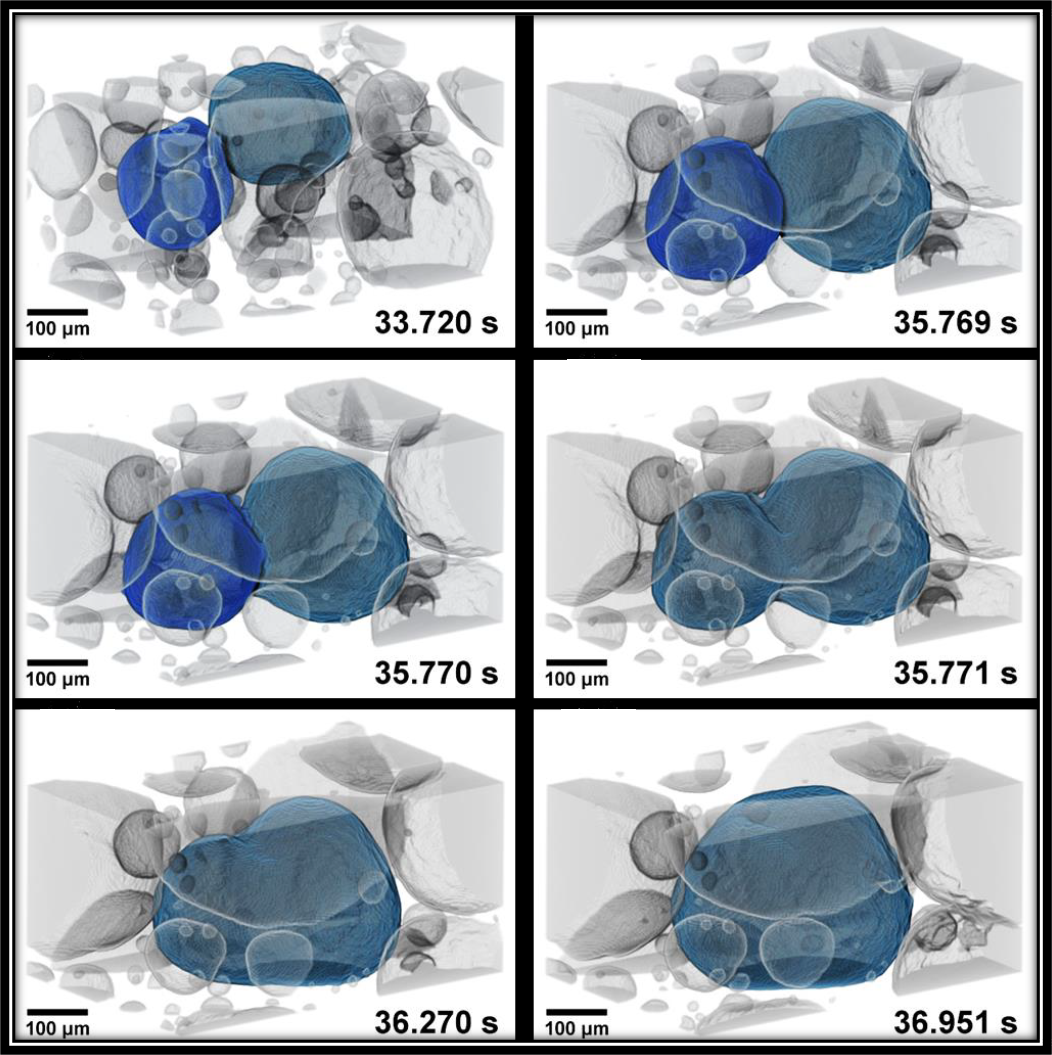

Such metal foams based on aluminum alloys are being investigated as lightweight materials, for example for the construction of electric cars. The morphology, size, and cross-linking of the bubbles are important to achieve the desired mechanical properties such as strength and stiffness in large components. Image Credit: Adv. Mat./PSI/HZB.

Such metal foams based on aluminum alloys are being investigated as lightweight materials, for example for the construction of electric cars. The morphology, size, and cross-linking of the bubbles are important to achieve the desired mechanical properties such as strength and stiffness in large components. Image Credit: Adv. Mat./PSI/HZB.

With 1000 tomograms per second, it is now palpable to non-destructively document quick processes and developments in materials on the micrometer scale, for example, the burning of a sparkler or the foaming of a metal alloy for the generation of stable lightweight materials.

Many individuals are familiar with computed tomography from medicine, where a part of the body is X-rayed from all sides, and then the calculation of a three-dimensional image is executed. This can be used to create any sectional images for diagnosis.

Fast 3D-Images with Synchrotron Radiation

This technique is a significant contribution to material analysis, nondestructive quality testing or the development of new functional materials. To analyze those materials with high special resolution and in the shortest possible time frame, a certain intense X-ray light of a synchrotron radiation source is needed.

Even fast changes and processes can be traced in the material samples can be imaged using the synchrotron beam if it is possible to obtain three-dimensional images in a short time sequence.

From 200 to 1000 Tomograms per Second

Dr. Francisco Garcia Moreno is leading a team at HZB to execute this project in association with researchers from the Swiss Light Source SLS at the Paul Scherrer Institute (PSI), Switzerland. A couple of years ago, the researchers managed to obtain a record 200 tomograms per second, referring to the technique of fast imaging tomoscopy.

The team has now made a new world record, with 1000 tomographs per second, thus it is now possible to record even faster processes in materials or during the manufacturing process.

The result was obtained without any major compromises in other parameters. The spatial resolution is still better at several micrometers and the field of view is several square millimeters. It is also possible to perform continuous record periods up to several minutes.

Rotary Table and High-Speed Camera

To obtain the X-ray images, the sample is positioned on a high-speed rotary table developed in-house, whose angular speed can be ideally synchronized with the acquisition speed of the camera.

We used particularly lightweight components for this rotary table so that it can reach 500 Hertz rotation speed stably.

Dr. Francisco Garcia Moreno, Research Lead, Helmholtz-Zentrum Berlin

TOMCAT beamline at the SLS has expertise in time-resolved X-ray imaging. PSI physicist Christian Schlepütz employed a new high-speed camera and special optics at the beamline.

“This increases the sensitivity very significantly, so that we can take 40 2D projections in one millisecond, from which we create a tomogram,” added Schlepütz. Faster measurements with higher spatial resolution can be achieved even from 2025 with the planned SLS 2.0 upgrade.

Processing the Data Stream

A huge data stream is created with the acquisition of 1000 three-dimensional data sets per second. This is performed over a period of just a few minutes. The data stream was initially stored at the PSI.

Dr. Paul Kamm at HZB was responsible for continued processing and quantitative assessment of the data. The raw data was reconstructed into 3D images remotely from HZB using the high-performance computers at PSI. The outcomes were then transferred to HZB for more quantification.

Sparklers, Dendrites and Bubbles

The researchers presented the power of tomoscopy using several examples from material research. The images revealed the extremely rapid changes that happened while the sparkler burned, as well as the formation of dendrites during the solidification of casting alloys or the growth and coalescence of bubbles in a liquid metal foam.

Such aluminum-based metal foams are analyzed as lightweight materials, for instance, for the purpose of building electric cars. The morphology, size and cross-linking of the bubbles are key to obtaining the required mechanical characteristics, such as strength and stiffness, in large components.

This method opens a door for the non-destructive study of fast processes in materials, which is what many research groups and also industry have been waiting for.

Dr. Francisco Garcia Moreno, Research Lead, Helmholtz-Zentrum Berlin

Journal Reference:

García-Moreno, F., et al. (2021) Tomoscopy: Time-Resolved Tomography for Dynamic Processes in Materials. Advanced Materials. doi.org/10.1002/adma.202104659.