Nov 16 2020

Scanning lasers, right from cameras integrated into the latest smartphones to barcode scanners used at supermarkets, are a crucial part of people’s daily lives. These lasers depend on detectors and lasers for pinpoint accuracy.

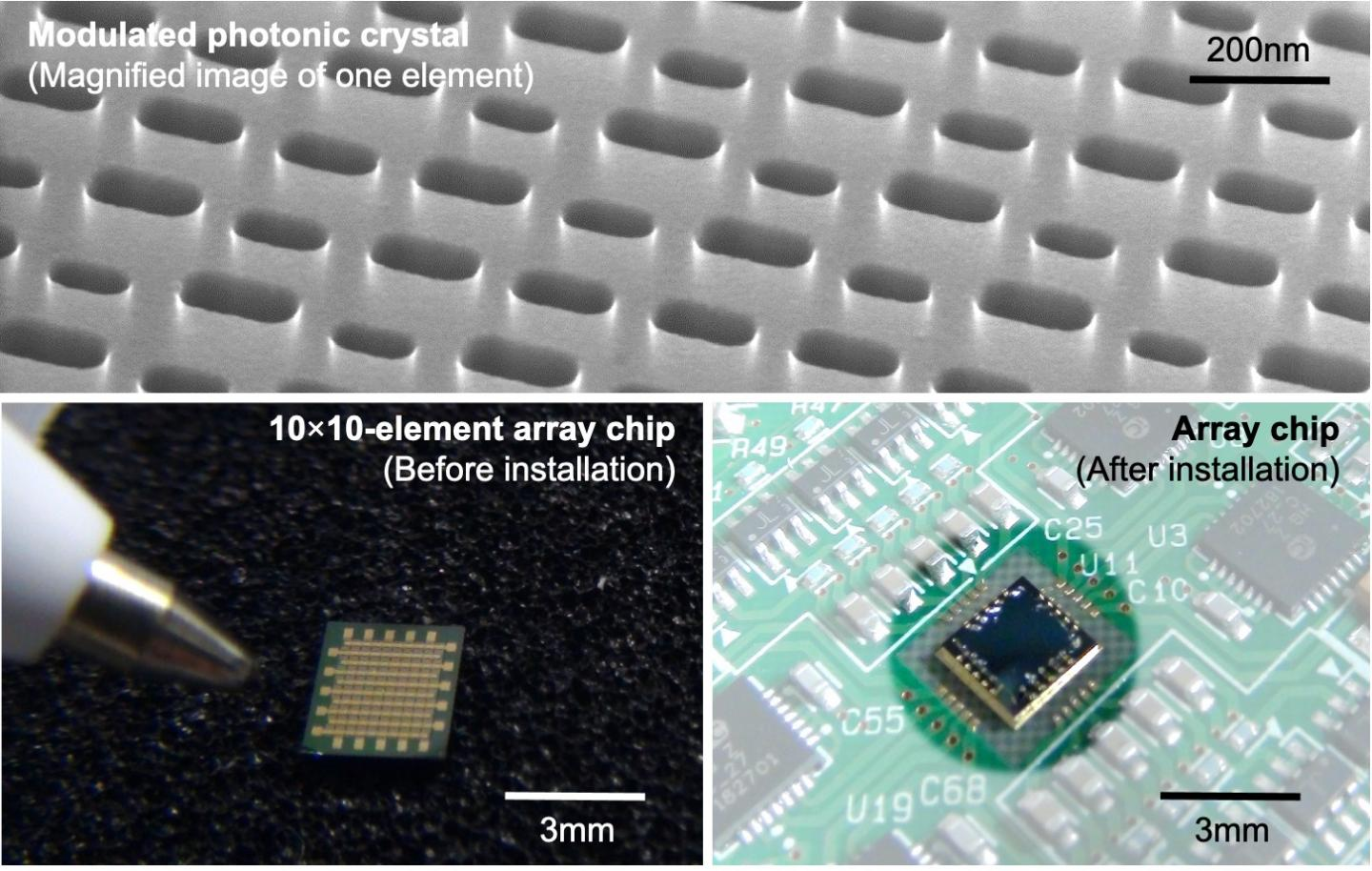

A seemingly random line of photonic crystals allows for laser beams to be emitted in various angles, allowing for more versatile and compact LiDAR technology. Image Credit: Kyoto University/Noda Lab.

A seemingly random line of photonic crystals allows for laser beams to be emitted in various angles, allowing for more versatile and compact LiDAR technology. Image Credit: Kyoto University/Noda Lab.

The use of LiDAR—a combination of radar and light—is becoming more common for detecting distance and objects. In LiDAR, the surrounding environment is recorded by reflected laser beams, offering key data for factory robots, agricultural machines, and autonomous cars.

Existing technology causes the laser beams to bounce off from moving mirrors—a mechanical technique that leads to inaccuracies and slower scanning speeds, and also results in complexity and large physical size of devices that accommodate mirrors and a laser.

A team of researchers from the Graduate School of Engineering at Kyoto University has elucidated a novel beam scanning device using “photonic crystals.” This device prevents the requirement for moving parts. The study was published in the Nature Communications journal.

Rather than organizing the crystals’ lattice points in an orderly array, the team discovered that changing the positions and shapes of the lattice points caused the laser beam to be produced in unusual directions.

What results is a lattice of photonic crystals that looks like a slab of Swiss cheese, where each crystal is calculated to emit the beam in a specific direction. By eliminating mechanical mirrors, we've made a faster and more reliable beam-scanning device.

Susumu Noda, Study Lead, Kyoto University

Photonic crystal lasers are essentially a type of “semiconductor laser”, the lattice points of which can be considered as nanoscale antennae, which, in turn, can be organized to cause a laser beam to be produced perpendicularly from the surface.

However, at first, the laser beam would only travel in a single direction on a 2D plane. Therefore, the researchers required more area to be covered.

Although the cyclic arrangement of the antennae positions led to an effective direction change, the deformed shape and a reduced power output made this solution impractical.

Modulating the antennae positions caused light emitted from adjacent antennae to cancel each other out, leading us to try changing antenna sizes. Eventually, we discovered that adjusting both position and size resulted in a seemingly random photonic crystal, producing an accurate beam without power loss. We called this a ‘dually modulated photonic crystal’.

Susumu Noda, Study Lead, Kyoto University

By arranging these photonic crystals—each developed to produce a beam in an unusual direction—in a matrix, the researchers were able to construct a compact, switchable, 2D beam scanner without the necessity for any mechanical components.

The researchers have effectively built a scanner that can emit beams in 100 different directions—that is, a resolution of 10×10. This has also been integrated with a diverging laser beam, leading to a novel type of LiDAR with more possibilities to recognize objects.

According to the researchers, additional refinements will allow the resolution to be increased by a factor of 900—that is, up to a 300×300 resolution range.

At first there was a great deal of interest in whether a structure that is seemingly so random could actually work. We now believe that eventually we will be able to develop a LiDAR system small enough to hold on a fingertip.

Susumu Noda, Study Lead, Kyoto University

Journal Reference:

Sakata, R., et al. (2020) Dually modulated photonic crystals enabling high-power high-beam-quality two-dimensional beam scanning lasers. Nature Communications. doi.org/10.1038/s41467-020-17092-w.