May 29 2008

BIOIDENT Technologies Inc., the leader in the development of mobile analytic and diagnostic systems, today announced that the company was awarded a contract for the Defense Advanced Research Projects Agency (DARPA) project "Printed Diagnostic Arrays". The goal of the project is to demonstrate the capabilities of biosensors with integrated printed optoelectronics. Together with the US Naval Research Laboratory (NRL), BIOIDENT is developing a portable multi-parameter detector in the form of a lab-on-a-chip system, for cost-effective point-of-use applications. The system combines microfluidics-based sensor arrays with BIOIDENT's printed optoelectronic sensor technology.

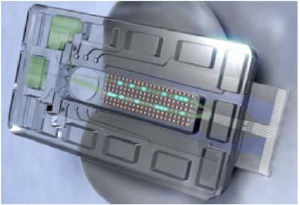

Illustration of a lab-on-a-chip system, combining microfluidics-based microarrays with printed organic sensor technology. The photodiodes printed directly onto the array read out the chemiluminescence signals (shown as bright green dots).

Illustration of a lab-on-a-chip system, combining microfluidics-based microarrays with printed organic sensor technology. The photodiodes printed directly onto the array read out the chemiluminescence signals (shown as bright green dots).

Mobile analytics and diagnostics are at the brink of a paradigm shift. The next generation of portable diagnostic systems will be able to efficiently perform multi-parameter measurements of tiny amounts of fluid samples, rapidly and with high precision at the point of use. However, the commercialization of such mobile applications has been hampered by the expensive and bulky optical readout equipment (lasers, CCD cameras, etc.) required with today’s systems. Eliminating expensive cameras and other optical components will reduce the size and cost of biosensor systems such as that previously developed by NRL, making a handheld sensor possible.

The goal of the DARPA-funded project is a proof of concept that printed sensors developed with BIOIDENT’s PhotonicLabTM Platform technology can enable the development of cost-effective and truly mobile lab-on-a-chip systems for the point of use. For this purpose, NRL’s original biosensor system design will be modified in two major ways: First the fluorescence assays used by NRL will be replaced with chemiluminescence assays. This eliminates the need for expensive laser excitation components. Second, the bulky readout unit (CCD camera and lens system) will be replaced with organic photodiodes, printed directly beneath the receptor antibodies in the microarray.

“Our printed optoelectronic technology makes it possible for the first time to integrate the functionality of expensive lasers and CCD cameras directly into the lab-on-a-chip system, and so to develop truly mobile, easy-to-use test equipment for the point of use,” noted Dr. Max Sonnleitner, CTO of BIOIDENT Technologies. “We are proud to work together with NRL and to set the standard in this significant and expanding market with our revolutionary technology.”

This technology is based on the use of organic semiconductor materials, which can be applied in liquid form onto glass or plastic foil substrates using printing technologies such as inkjet or screen print. The integration of the readout system directly onto the chip enables a minimal sample-sensor distance, providing signal detection with very high sensitivity.

Microfluidic systems typically contain several reaction chambers with different reagents, simultaneously testing for the presence of multiple materials such as toxins, bacteria, viruses, and even explosives. The potential applications for this detector system range from multi-parameter detection of chemical and biological agents to medical diagnostics to environmental and food testing.

“Our array biosensor offers the functionality of a laboratory and yet is integrated into a box weighing less than six kilograms (thirteen pounds),” said Dr. Frances Ligler, NRL’s Project Leader. “However, because we are aiming for an even more compact form, we need an alternative to the bulky optical components such as lasers and CCD cameras. The promising printed optoelectronics approach from BIOIDENT is very attractive to us, and we look forward to an exciting partnership.”