Aug 17 2020

At the National Institute of Standards and Technology (NIST), researchers have developed a novel design for light-emitting diodes (LEDs), which could help address a long-standing drawback in the efficiency of light sources.

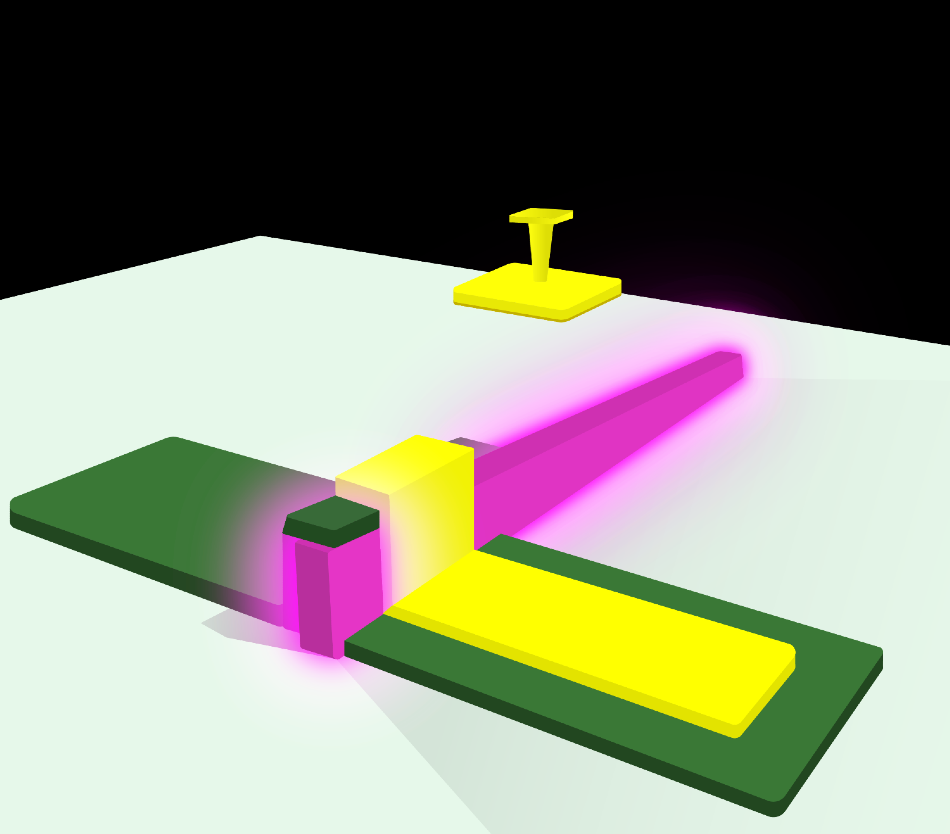

The fin LED pixel design includes the glowing zinc oxide fin (purple), isolating dielectric material (green), and metal contact (yellow atop green). The microscopic fins, which the research team arranged into comb-like arrays, show an increase in brightness of 100 to 1,000 times over conventional submicron-sized LED designs. Image Credit: B. Nikoobakht, N. Hanacek/NIST.

The fin LED pixel design includes the glowing zinc oxide fin (purple), isolating dielectric material (green), and metal contact (yellow atop green). The microscopic fins, which the research team arranged into comb-like arrays, show an increase in brightness of 100 to 1,000 times over conventional submicron-sized LED designs. Image Credit: B. Nikoobakht, N. Hanacek/NIST.

The researchers illustrated the concept by using microscopic LEDs in the laboratory, realizing a drastic increase in brightness and the potential to develop laser light—all properties that could render it useful in a range of miniaturized and large-scale applications.

The NIST researchers also collaborated with researchers from the University of Maryland, Rensselaer Polytechnic Institute, and the IBM Thomas J. Watson Research Center on this study. The team has described the study in a paper published recently in the peer-reviewed journal Science Advances.

The new device exhibits about 100 to 1,000 times increase in the brightness when compared to traditional small, submicron-sized LED designs.

“It’s a new architecture for making LEDs,” said NIST’s Babak Nikoobakht, who invented the new design. “We use the same materials as in conventional LEDs. The difference in ours is their shape.”

LEDs have been in existence for several years, but the creation of bright LEDs won a Nobel prize and led to a new era of lighting. But even modern LEDs have a drawback that disappoints the designers.

To some extent, supplying an LED with more electricity makes it shine very bright, but the brightness decreases soon, rendering the LED highly inefficient. Named “efficiency droop” in industrial terms, the problem prevents the use of LEDs in various potential applications, ranging from the destruction of viruses to communications technology.

Although the novel LED design prevents the drop in efficiency, at first, the team did not seek to resolve this issue. Their main objective was to make a microscopic LED for use in minuscule applications such as the lab-on-a-chip technology sought by researchers at NIST and elsewhere.

The researchers experimented with a completely new design for the part of the LED that shines: In contrast to the flat, planar design used in traditional LEDs, the team developed a light source using long, thin zinc oxide strands known as fins. (Long and thin are just relative terms—Each fin measures only around 5 μm in length, extending about one-tenth of the way across the breadth of an average strand of human hair).

Their fin array resembles a tiny comb with the ability to extend to regions as large as 1 cm or more.

We saw an opportunity in fins, as I thought their elongated shape and large side facets might be able to receive more electrical current. At first, we just wanted to measure how much the new design could take. We started increasing the current and figured we’d drive it until it burned out, but it just kept getting brighter.

Babak Nikoobakht, Researcher, National Institute of Standards and Technology

The innovative design of the researchers glowed brightly in wavelengths close to the border between violet and ultraviolet, producing around 100 to 1,000 times as much power as standard tiny LEDs. Nikoobakht describes the finding as a crucial fundamental discovery.

“A typical LED of less than a square micrometer in area shines with about 22 nanowatts of power, but this one can produce up to 20 microwatts,” Nikoobakht added. “It suggests the design can overcome efficiency droop in LEDs for making brighter light sources.”

It’s one of the most efficient solutions I have seen. The community has been working for years to improve LED efficiency, and other approaches often have technical issues when applied to submicrometer wavelength LEDs. This approach does the job well.

Grigory Simin, Professor of Electrical Engineering, University of South Carolina

Simin was not involved in the study.

In addition, the research team achieved another fascinating breakthrough as they increased the current. Although the LED glowed in an array of wavelengths initially, its relatively broad emission ultimately narrowed to two wavelengths of strong violet color. The reason became evident: Their tiny LED had turned into a tiny laser.

Converting an LED into a laser takes a large effort. It usually requires coupling a LED to a resonance cavity that lets the light bounce around to make a laser. It appears that the fin design can do the whole job on its own, without needing to add another cavity.

Babak Nikoobakht, Researcher, National Institute of Standards and Technology

A tiny laser would be crucial for chip-scale applications not just for chemical sensing but also for high-definition displays, disinfection, and next-generation hand-held communications products.

“It’s got a lot of potential for being an important building block,” stated Nikoobakht. “While this isn’t the smallest laser people have made, it’s a very bright one. The absence of efficiency droop could make it useful.”

The study was financially supported in part by the U.S. Army Cooperative Research Agreement.

Journal Reference

Nikoobakht, B., et al. (2020) High-brightness lasing at submicrometer enabled by droop-free fin light-emitting diodes (LEDs). Science Advances. doi.org/10.1126/sciadv.aba4346.