Jul 3 2020

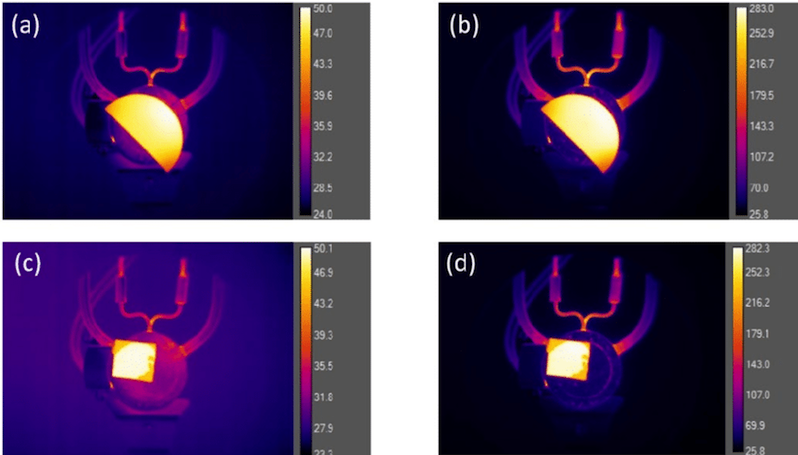

An infrared image of the fused silica window used to test the depth thermography concept. For the project, the team heated the silica, a type of glass, and analyzed it using a spectrometer. They then measured temperature readings from various depths of the sample. Image Credit: Mikhail Kats.

Engineers at the University of Wisconsin–Madison (UW–Madison) have used a new technique termed depth thermography to remotely find the temperature beneath the surface of specific materials.

The technique could prove useful in applications where conventional temperature probes are not applicable, for example, monitoring the performance of semiconductors or next-generation nuclear reactors.

Several temperature sensors quantify thermal radiation, a major part of which lies in the infrared spectrum, radiated off the surface of an object. The temperature of the object is directly proportional to the amount of radiation it emits, which forms the basis for gadgets such as thermal imaging cameras.

However, depth thermography reaches further down the surface and works with a specific family of materials that are partially transparent to infrared radiation.

We can measure the spectrum of thermal radiation emitted from the object and use a sophisticated algorithm to infer the temperature not just on the surface, but also underneath the surface, tens to hundreds of microns in. We’re able to do that precisely and accurately, at least in some instances.

Mikhail Kats, Professor of Electrical and Computer Engineering, University of Wisconsin–Madison

The technique has been described by Kats, his research associate Yuzhe Xiao, and other collaborators in the ACS Photonics journal this spring.

As part of the study, the researchers used a spectrometer to analyze a heated piece of fused silica, a type of glass. Then, temperature readings from different depths of the sample were measured using computational tools developed earlier by Xiao, using which he calculated the thermal radiation emitted from objects composed of multiple materials.

The researchers worked backward and used the algorithm to find the temperature gradient that fits best with the experimental results.

According to Kats, this specific effort was a proof of principle. Kats believes that in future studies, the technique could be applied to more complex multilayered materials and intends to apply machine learning techniques to enhance the process.

His ultimate aim is to use depth thermography to quantify semiconductor devices to understand about their temperature distributions while they work.

That is just not the only prospective application of the method. 3D temperature profiling of this type could even be used to quantify and map clouds of high-temperature gases and liquids.

For example, we anticipate relevance to molten-salt nuclear reactors, where you want to know what’s going on in terms of temperature of the salt throughout the volume. You want to do it without sticking in temperature probes that may not survive at 700 degrees Celsius for very long.

Mikhail Kats, Professor of Electrical and Computer Engineering, University of Wisconsin–Madison

Moreover, he added that the technique could help measure the optical properties and thermal conductivity of materials without the need to use temperature probes.

This is a completely remote, non-contact way of measuring the thermal properties of materials in a way that you couldn’t do before.

Mikhail Kats, Professor of Electrical and Computer Engineering, University of Wisconsin–Madison

Other contributors to the study are Yuzhe Xiao, Chenghao Wan, Alireza Shahsafi, and Jad Salman from UW–Madison.

The study was financially supported by grants from the Department of Defense (N00014-16-1-2556) and the Department of Energy (DE-NE0008680).

Journal Reference

Xiao, Y., et al. (2020) Depth Thermography: Noninvasive 3D Temperature Profiling Using Infrared Thermal Emission. ACS Photonics. doi.org/10.1021/acsphotonics.9b01588.