Jun 15 2020

For the first time, researchers at the Helmholtz-Zentrum Berlin (HZB) and Humboldt-Universität zu Berlin have successfully used a hybrid perovskite semiconductor material to produce light-emitting diodes (LEDs) with the help of inkjet printing.

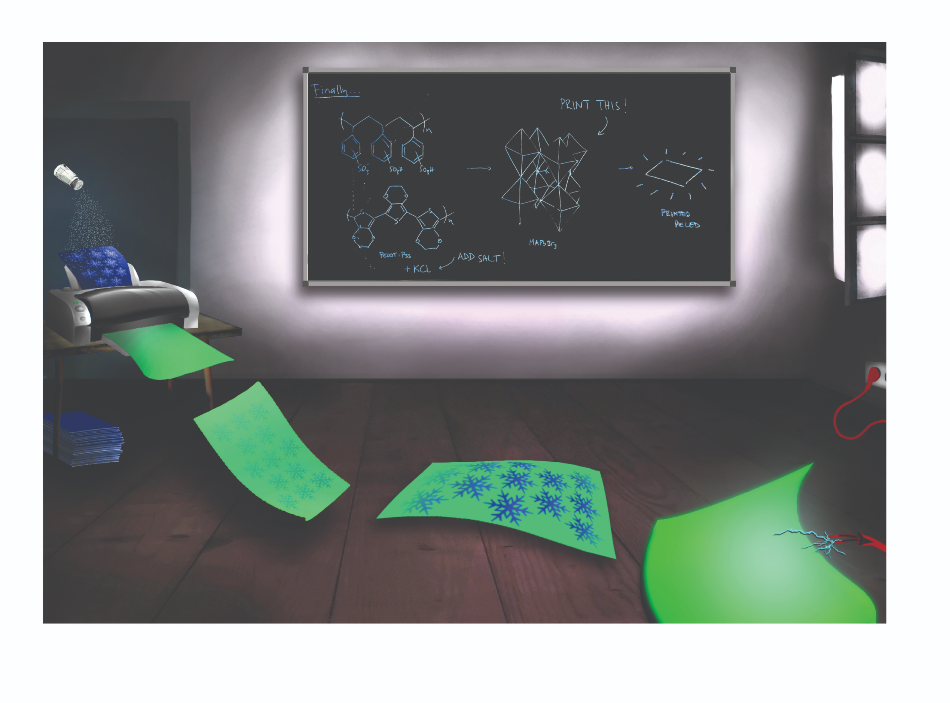

Graphic representation of the printing process for the perovskite LED. Image Credit: © Claudia Rothkirch/HU Berlin.

Graphic representation of the printing process for the perovskite LED. Image Credit: © Claudia Rothkirch/HU Berlin.

The study paves the way for the extensive application of these materials to produce several different types of electronic components. The researchers achieved the advancement using a trick—they “inoculated” (or seeded) the surface with crystals of particular type.

The field of microelectronics involves the use of various functional materials that exhibit properties making them ideal for particular applications. For instance, data storage devices and transistors are made of silicon, and at present, a majority of the photovoltaic cells used for producing electricity from sunlight are also made of this semiconductor material.

On the other hand, in optoelectronic elements such as LEDs, compound semiconductors like gallium nitride are utilized to produce light. The manufacturing methods also vary for the materials of different classes.

Transcending the Materials and Methods Maze

Hybrid perovskite materials exhibit the potential for simplification—through the arrangement of the inorganic and organic components of semiconducting crystal in a particular structure.

They can be used to manufacture all kinds of microelectronic components by modifying their composition. They can be produced from a liquid solution, so you can build the desired component one layer at a time directly on the substrate.

Emil List-Kratochvil, Professor and Head, Joint Research Group, Helmholtz-Zentrum Berlin and Humboldt-Universität zu Berlin

Furthermore, it is relatively simple to process perovskite crystals.

First Solar Cells from an Inkjet Printer, Now LEDs Too

In recent years, the HZB researchers have already demonstrated it is possible to print solar cells from a solution of semiconductor compounds. Currently, they are the global pioneers in this technology. At present, for the first time, the collaborative team of HZB and HU Berlin has successfully produced functional LEDs using the same method.

To this end, a metal halide perovskite was used by the researchers since this material exhibits the potential for specifically high efficiency in producing light. However, it is difficult to process.

Until now, it has not been possible to produce these kinds of semiconductor layers with sufficient quality from a liquid solution.

Emil List-Kratochvil, Professor and Head, Joint Research Group, Helmholtz-Zentrum Berlin and Humboldt-Universität zu Berlin

For instance, although it is possible to print LEDs just using organic semiconductors, these offer only moderate luminosity. “The challenge was how to cause the salt-like precursor that we printed onto the substrate to crystallise quickly and evenly by using some sort of an attractant or catalyst,” elucidated List-Kratochvil.

For this purpose, the researchers chose a seed crystal—a salt crystal that binds itself to the substrate and activates the formation of a gridwork for the subsequent perovskite layers.

Considerably Better Electronic and Optical Characteristics

The team developed printed LEDs with considerably higher luminosity and better electrical properties than could be realized earlier using additive manufacturing processes.

However, for List-Kratochvil, this success is just an intermediate stage on the path to future micro- and optoelectronics, which he hopes will be based solely on hybrid perovskite semiconductors.

The advantages offered by a single universally applicable class of materials and a single cost-effective and simple process for manufacturing any kind of component are striking.

Emil List-Kratochvil, Professor and Head, Joint Research Group, Helmholtz-Zentrum Berlin and Humboldt-Universität zu Berlin

He intends to finally produce all crucial electronic components in this manner in the HZB and HU Berlin laboratories.

List-Kratochvil is Professor of Hybrid Devices at the Humboldt-Universität zu Berlin and head of a Joint Lab launched in 2018, operated by HU in partnershipwith HZB.

A team of researchers jointly led by List-Kratochvil and HZB scientist Dr Eva Unger is now working in the Helmholtz Innovation Lab HySPRINT to develop coating and printing processes—also technically called as “additive manufacturing”—for hybrid perovskites. These are crystals that have a perovskite structure with both organic and inorganic components.

Journal Reference:

Hermerschmidt, F., et al. (2020) Finally, inkjet-printed metal halide perovskite LEDs – utilizing seed crystal templating of salty PEDOT:PSS. Materials Horizons. https://doi.org/10.1039/d0mh00512f