May 29 2020

Scientists have devised a new technique to create programmable integrated, power-efficient switching units on a silicon photonics chip.

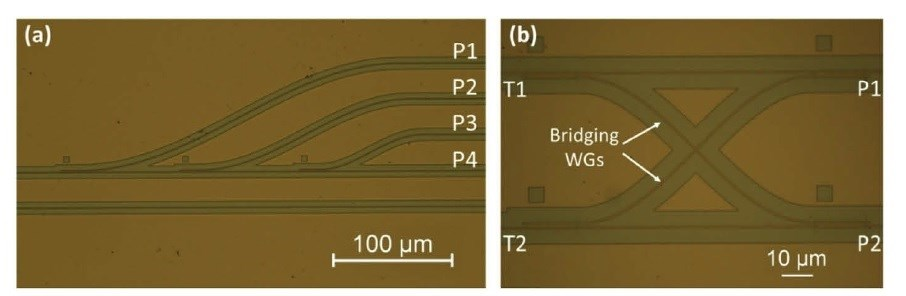

The researchers developed a method for making configurable silicon photonics circuits. They used it to fabricate a 1 x 4 programmable photonic switching circuit that produces an output at one of four ports (P1-P4) (a) and a 2 x 2 photonic switching circuit with two output ports (P1, P2) (b). Image Credit: Xia Chen, University of Southampton.

The researchers developed a method for making configurable silicon photonics circuits. They used it to fabricate a 1 x 4 programmable photonic switching circuit that produces an output at one of four ports (P1-P4) (a) and a 2 x 2 photonic switching circuit with two output ports (P1, P2) (b). Image Credit: Xia Chen, University of Southampton.

With the help of this novel technology, researchers can fabricate generic optical circuit in bulk and then program it for particular applications, like LIDAR circuits, communications systems, or computing applications. This advancement may help decrease production costs.

Silicon photonics is capable of integrating optical devices and advanced microelectronic circuits all on a single chip. We expect configurable silicon photonics circuits to greatly expand the scope of applications for silicon photonics while also reducing costs, making this technology more useful for consumer applications.

Xia Chen, Research Team Member, University of Southampton

Headed by Graham Reed, the researchers showed how this latest method in switching units can be used as building blocks for producing programmable, larger chip-based photonic circuits. They have described their new technique in Optics Express—a journal from The Optical Society (OSA).

The technology we developed will have a wide range of applications. For example, it could be used to make integrated sensing devices to detect biochemical and medical substances as well as optical transceivers for connections used in high-performance computing systems and data centers.

Xia Chen, Research Team Member, University of Southampton

Erasable Components

The latest research builds on previous studies in which an erasable version of an optical component—called a grating coupler—was developed by embedding germanium ions into the silicon.

Such ions cause damage that alters the refractive index of silicon in that region. By heating the local area through a laser annealing process, this refractive index can be reversed and the grating coupler can be erased.

In the Optics Express article, the scientists revealed how the same germanium ion implantation method was used for producing erasable directional couplers and waveguides—parts that can be employed to develop reconfigurable switches and circuits. This is the first study to demonstrate the development of sub-micron erasable waveguides on silicon.

We normally think about ion implantation as something that will induce large optical losses in a photonic integrated circuit. However, we found that a carefully designed structure and using the right ion implantation recipe can create a waveguide that carries optical signals with reasonable optical loss.

Xia Chen, Research Team Member, University of Southampton

Building Programmable Circuits

The researchers demonstrated the novel method by engineering and producing directional couplers, waveguides, and 1 x 4 and 2 x 2 switching circuits, using the Cornerstone fabrication foundry of the University of Southampton. Reliable performance was shown by photonic devices obtained from different chips. These devices had been tested both before and after programming with laser annealing.

In this method, the routing of the photonic waveguide is physically changed through a one-time operation, and hence, no extra power is required to maintain the configuration when programmed.

The scientists have also found that both laser annealing and electrical annealing, using a local in-built heater, can be employed to program the circuits.

The scientists are working with a firm called ficonTEC to render this new technology feasible beyond the laboratory setting. Their aim is to develop a method to apply the laser and/or electrical annealing process at wafer-scale, through a traditional wafer prober (wafer testing machine), so that an unlimited number of chips can possibly be programmed automatically.

The researchers are now working to incorporate the electrical and laser annealing processes into such a wafer-scale prober—a device present in a majority of electronic-photonic foundries—that is being tested at the University of Southampton.

The study is part of a project that was financially supported by the Engineering and Physical Sciences Research Council to redefine silicon photonics and bring it to commercial markets.

Journal Reference:

Chen, X., et al. (2020) Silicon erasable waveguides and directional couplers by germanium ion implantation for configurable photonic circuits. Optics Express. doi.org/10.1364/OE.394871.