Apr 10 2020

Many electronic devices, including digital cameras, often require light-responsive sensors. To meet the growing demand for these kinds of optoelectronic components, the industry is looking for innovative semiconductor materials.

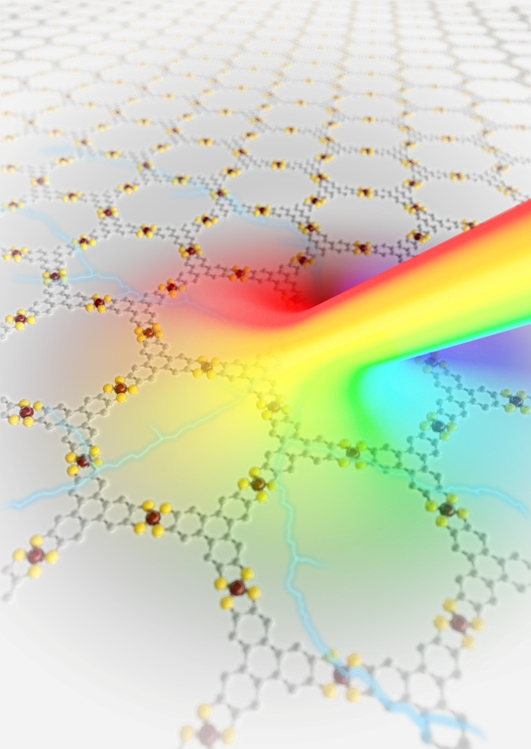

Physicists of HZDR and TU Dresden have developed a photodetector, which is completely based on layers of metal-organic frameworks. Since this compound can detect and transform a broad range of light wavelengths into electrical signals, it could become a novel detector material. Image Credit: HZDR/Juniks.

Physicists of HZDR and TU Dresden have developed a photodetector, which is completely based on layers of metal-organic frameworks. Since this compound can detect and transform a broad range of light wavelengths into electrical signals, it could become a novel detector material. Image Credit: HZDR/Juniks.

But semiconductor materials are expected not only to cover a wide range of wavelengths and, at the same time, they also need to be cheap. And now, both these requirements can be fulfilled by a hybrid material created in Dresden.

Physics Ph.D. student Himani Arora at Helmholtz-Zentrum Dresden-Rossendorf (HZDR) have shown that this hybrid material—that is, metal-organic framework (MOF)—can be utilized as a broadband photodetector. Since this material lacks cost-intensive raw materials, it can be created in large amounts that too in an economical way.

In the last two decades, MOFs have turned out to be a sought-after material system. To date, these extremely porous substances, up to 90% of which contain vacant space, have mostly been used for catalysis, for storing gases, or to gradually discharge medicines into the human body.

The metal-organic framework compound developed at TU Dresden comprises an organic material integrated with iron ions. The special thing about it is that the framework forms superimposed layers with semiconducting properties, which makes it potentially interesting for optoelectronic applications."

Dr. Artur Erbe, Head of “Transport in Nanostructures” Group, Institute of Ion Beam Physics and Materials Research, HZDR

The researchers conceptualized the idea of applying the novel semiconducting two-dimensional (2D) MOF as a photodetector. To follow this idea further, Himani Arora examined the electronic characteristics of the semiconductor.

She primarily analyzed the extent to which light sensitivity depended on wavelength and temperature—and eventually reached a potential conclusion: the semiconductor could identify a wide range of light wavelengths from 400 to 1575 nm. Therefore, the radiation spectrum goes from ultraviolet to near-infrared range.

This is the first time we have proved such a broadband photodetection for a photodetector completely based on MOF layers. These are ideal properties for using the material as an active element in optoelectronic components."

Himani Arora, Ph.D. Student, Institute of Ion Beam Physics and Materials Research, HZDR

Small Bandgap Makes for Efficiency

The wavelength spectrum, which can be covered and converted into electrical signals by a semiconducting material, essentially relies on what is known as bandgap. Experts employ this term to elucidate the energetic distance that exists between the conduction band and the valence band of a solid-state material. In standard semiconductors, the valence band is entirely full, and therefore the electrons can no longer move around.

By contrast, the conduction band is predominantly vacant, and therefore the electrons can freely move around and thus have an impact on the flow of current. While insulators have a huge bandgap that prevents the electrons from moving from the valance band to the conduction band, which is not present in metal conductors.

By using the light waves, the bandgap in a semiconductor is big enough to take the electrons to the higher energy level of the conduction band. If the bandgap is smaller, then a lesser amount of energy is needed to stimulate an electron.

As the bandgap in the material we explored is very small, only very little light energy is required to induce the electricity. This is the reason for the large range of the detectable spectrum.

Himani Arora, Ph.D. Student, Institute of Ion Beam Physics and Materials Research, HZDR

When the detector is cooled down to lower temperatures, the performance can further be enhanced because the electrons’ thermal excitation is considerably inhibited. Other enhancements include improving the configuration of components, creating more consistent contacts, and optimizing the material further.

The outcomes of the study indicate that the new MOF-based photodetectors will have a promising future.

The combination of low-cost manufacturing process and electronic properties, make the MOF layers as potential candidates for a wide range of optoelectronic applications.

“The next step is to scale the layer thickness,” added Artur Erbe. “In the study, 1.7 micrometer MOF films were used to build the photodetector. To integrate them into components, they need to be significantly thinner.”

If feasible, the goal is to minimize the superimposed layers to 70 nm, that is, 25 times smaller than that of their original size. The material reduced to a layer of this thickness should display similar characteristics.

If the researchers can establish that the functionality continues to be the same in these considerably thinner layers, they can subsequently proceed to the production stage.