Feb 5 2020

Around one in six people in the United States suffer from foodborne illnesses every year. According to the Centers for Disease Control and Prevention, 48 million people in the country become sick because of one or more of 31 identified pathogens, such as E. coli O157:H7, which is known to be a particularly harsh strain of E. coli.

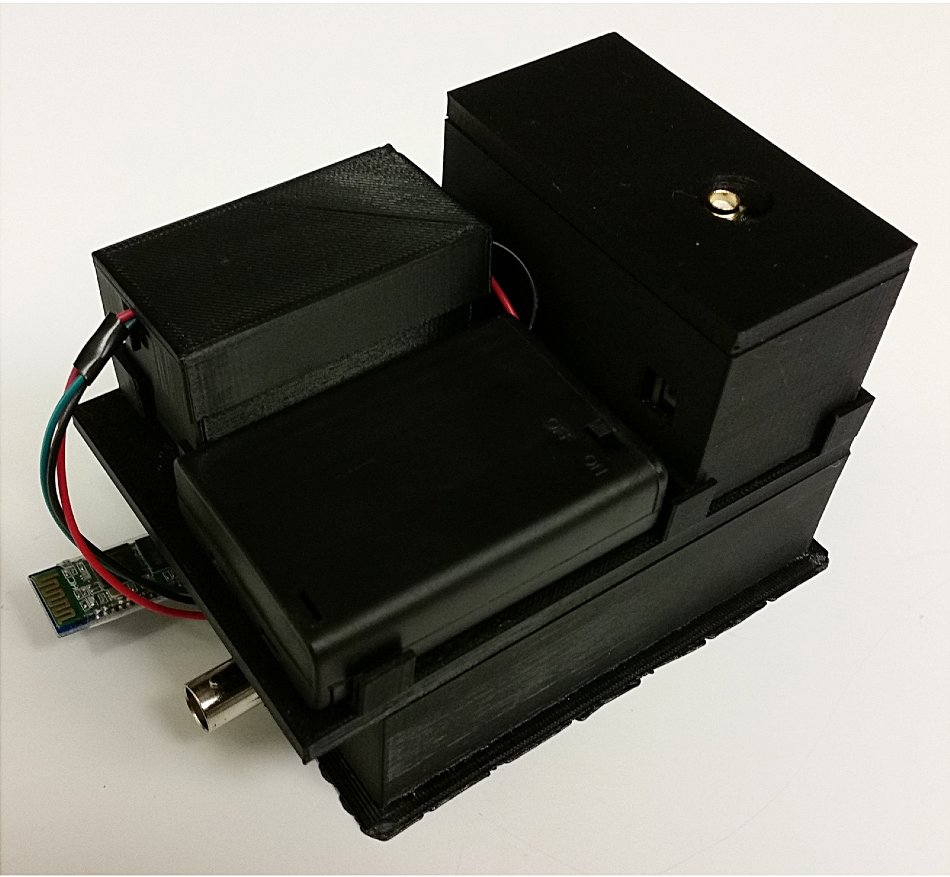

Researchers from Purdue created a portable device that works with smartphones and laptops to do on-site testing for E. coli in food samples. Image Credit: Purdue University.

Researchers from Purdue created a portable device that works with smartphones and laptops to do on-site testing for E. coli in food samples. Image Credit: Purdue University.

At Purdue University, scientists have been exploring ways to create new technologies to prevent the spread of foodborne illnesses, which account for 3,000 deaths every year in the United States, by identifying them in a more efficient manner.

The researchers have created a bioluminescence-based assay fixed to a hand-held device that operates with both laptops and smartphones to execute on-site testing for dangerous E. coli present in food samples.

Using low light from the bioluminescent assay, the silicon photomultiplier (SiPM) device identifies the presence of bacteria that are responsible for causing foodborne illness in food samples.

The researchers at Purdue University also developed an electrical circuit with a microcontroller, amplifier, and comparator to convey the information to smartphones and laptops through Bluetooth technology. The team utilized 3D printing to develop a hand-held cradle for the SiPM device. The study was published in the January edition of Applied Optics.

Our goal is to create technology and a process that allows for the cost-effective detection of the causes of foodborne illness using an easy, expedient and efficient process. This time frame allows for better integrated detection and quicker action to stop more people from getting sick.

Euiwon Bae, Senior Research Scientist, School of Mechanical Engineering, College of Engineering, Purdue University

Bae developed the technology in association with Bruce Applegate, a professor of food science in the College of Agriculture of Purdue University.

To demonstrate the proof of concept, the researchers at Purdue University tested the device by using ground beef samples that were artificially contaminated. The beef was obtained from a local grocery store.

The E. coli was then injected into the ground beef samples and the SiPM device was subsequently used to examine the sample in less than 10 hours of inoculation. The beef was later washed and incubated with an enrichment liquid that contained a modified phage—a virus for bacteria.

This modified phage subsequently infects deadly foodborne bacteria so that upon adding a substrate, the bacteria produce light. This light is detected by the SiPM device, which is also capable of counting photons or light pulses.

Our assay offers higher sensitivity, lower cost, better portability and other distinct advantages when compared to existing detection methods.

Bruce Applegate, Professor, Food Science, College of Agriculture, Purdue University

Applegate developed the unique modified phage utilized with smartphone technology, which is being marketed by a Purdue University-affiliated startup, Phicrobe. The startup was established by Applegate.

The technology research was funded by the Center for Food Safety Engineering (CFSE) and the U.S. Department of Agriculture Agricultural Research Service (ARS), in addition to Hatch Funds that support agricultural studies at land-grant institutions throughout the United States.

To patent the technology, the researchers are working with the Purdue Research Foundation Office of Technology Commercialization, and are also seeking partners.