Jan 8 2020

Following a heavy storm, it is customary to investigate a part of an airplane or the blade of a wind turbine, whether it has been loaded beyond a certain threshold or hit by hailstones, even if there is no visible damage.

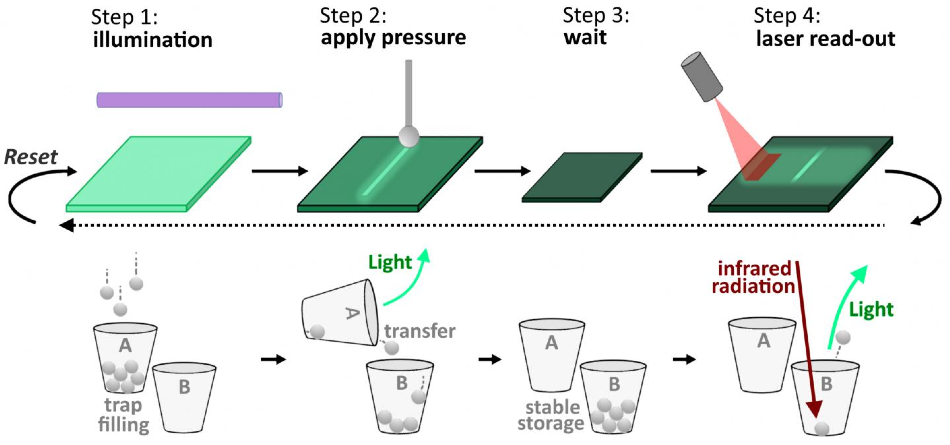

In the first step, the luminescent material is illuminated with UV or blue light. Mainly traps of type A are filled with electrons. In step 2, the materials light up where pressure is applied. In addition, part of the trapped electrons are transferred from trap A to trap B. Trap B is very stable keeping the electrons stored for up to three days (step 3). In step 4, the material is scanned with an infrared laser beam. The areas where pressure had been previously applied, light up in green once more. When the material is illuminated again, the whole process can be repeated. Image Credit: LumiLab research group, Department of Solid State Sciences, Ghent University.

In the first step, the luminescent material is illuminated with UV or blue light. Mainly traps of type A are filled with electrons. In step 2, the materials light up where pressure is applied. In addition, part of the trapped electrons are transferred from trap A to trap B. Trap B is very stable keeping the electrons stored for up to three days (step 3). In step 4, the material is scanned with an infrared laser beam. The areas where pressure had been previously applied, light up in green once more. When the material is illuminated again, the whole process can be repeated. Image Credit: LumiLab research group, Department of Solid State Sciences, Ghent University.

Scientists from Ghent University in Belgium have created a pressure-sensitive light-emitting material with the ability to visualize the location a hit occurred, up to three days following an event. They discovered this by developing what is known as a mechanoluminescent material, which exhibits particular sensitivities to pressure (or mechanical action) and infrared radiation.

Mechanoluminescent materials are a particular family of luminescent materials with the ability to emit light upon being deformed or upon applying pressure to them. Although this process has been known for several hundred years—by crushing a few crystals of sugar in a dark place, sparks of light can be observed—in the majority of materials it is related to the disintegration of chemical bonds in crystals.

This kind of destructive mechanoluminescence is not useful for sensing and monitoring of the structural integrity of constructions. A number of materials have been proposed and created in the past, with the ability to repeatedly emit light when pressure is applied.

The basis for the majority is the storage of energy in the luminescent materials crystal lattice upon being exposed to UV or ambient light. Upon applying pressure, the stored energy is discharged in the form of light. The amount of deformation or pressure is directly proportional to the strength of the obtained signal, enabling a broad range of stresses in materials to be quantified, with optimal spatial resolution over larger areas.

One drawback when used for various applications is that it is essential to consistently monitor the mechanoluminescent emission, as it arises only upon applying pressure.

In a new study reported in Light Science & Applications, researchers from the LumiLab research group have added memory to a particular mechanoluminescent material. They have made use of defects (or imperfections) in this material in a selective manner, thus visualizing the place of application of pressure, up to three days following the deformation of the material took place.

Summarizing the operational principle of the method, authors Robin Petit, Ang Feng, Simon Michels, and Philippe Smet stated, “Mechanoluminescent material was incorporated in polymer plates and briefly exposed to ultraviolet light. During this illumination, defects in the material are populated with electrons originating from the luminescent centers.”

When pressure is applied to the luminescent material, these electrons are released again from the defects, or traps, as we commonly call them. Some of the released electrons return to the luminescent centers, with the emission of light as a consequence. This is the standard mechanoluminescence process. A fraction of the released electrons are however transferred to other types of defects.

Robin Petit, Ang Feng, Simon Michels, and Philippe Smet, Study Authors, Ghent University

The authors added, “Those defects are called ‘deep traps’ as the electrons are not easily released again, except when infrared light is used. By scanning an infrared laser beam over the sample surface, those areas where electrons had been stored after the application of pressure light up as soon as the infrared photons are kicking them out of their traps. The electrons return to the luminescent center and the material locally lights up again.”

More importantly, various kinds of defects in the luminescent material can respond in different ways to stimuli like pressure, light, or heat. Therefore, it would be possible to move electrons by pressure—the “write” action—and then “read out” through optical means. The deep traps are highly stable; therefore, the researchers could show that the signal was still visible even after three days between the “write” and “read” steps.

However, the scientists’ study is far from being completed. Firstly, they intend to enhance the mechanoluminescent material’s sensitivity, optimizing the write and read conditions. Secondly, they want to make the material applicable to particular applications in which optimal use of the memory function can be leveraged.

Think of components of buildings, vehicles or infrastructure where constant monitoring is not possible.

Philippe Smet, Study Author, Ghent University

“Furthermore, this approach will not only help the development of new pressure indicating materials. This work also revealed that the defects responsible in the energy storage and read out process are not of a single type,” the researchers stated.

This insight will prove beneficial for the development of other light-emitting materials, where researchers use defects for other purposes or try even to suppress the occurrence of defects. Think of LED lamps which might be even more efficient in the conversion of electricity to light, brighter glow-in-the-dark materials or faster scintillating materials used in medical imaging.

Robin Petit, Ang Feng, Simon Michels, and Philippe Smet, Study Authors, Ghent University