Optical non contact measurement systems do not require physical contact with a surface to determine the dimensions and other parameters of a component. Instead new systems use a light source which is passed through a range of optics and is then generated on the surface to be measured.

The main benefit of optical non contact measurement system is removing the risk of scratching or damaging components through contact.

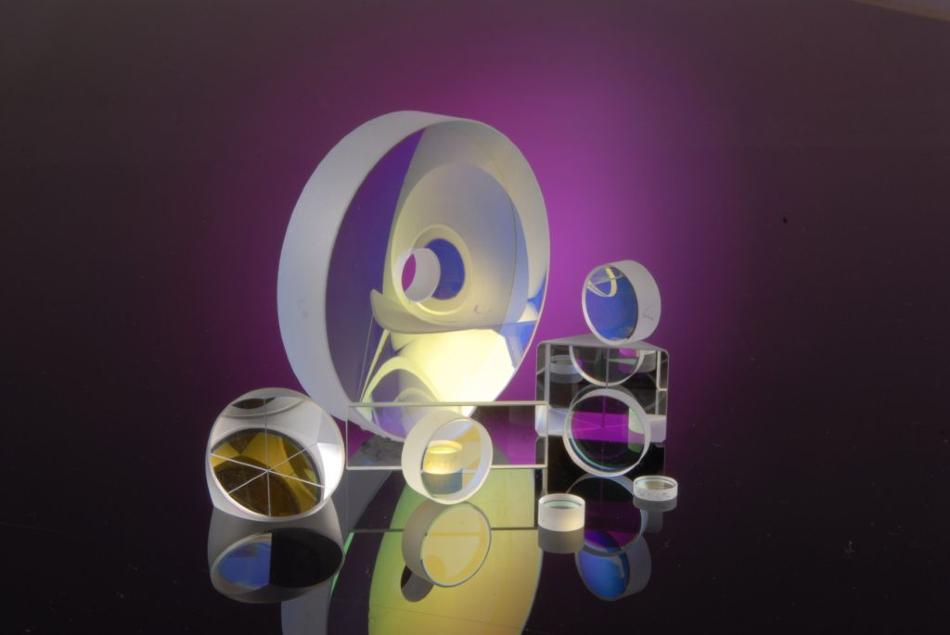

LASER COMPONENTS can provide a range of optical components including lenses, protective windows, prisms, optical filters and mirrors which are incorporated in the instrument. These components can be provided using a range of materials including BK7, borosilicate and UV Fused silica. In additional these components can be provided with a range of coatings including high efficiency AR coatings to ensure minimal signal losses, dichroic filters and beamsplitter coatings and more.