Oct 31 2019

Materials scientist Jeffrey Pyun from the University of Arizona presented his first generation of orange-tinted plastic lens five years ago to optical scientist Robert Norwood, who replied, “This isn’t the ’60s. No one wants orange glasses, man.”

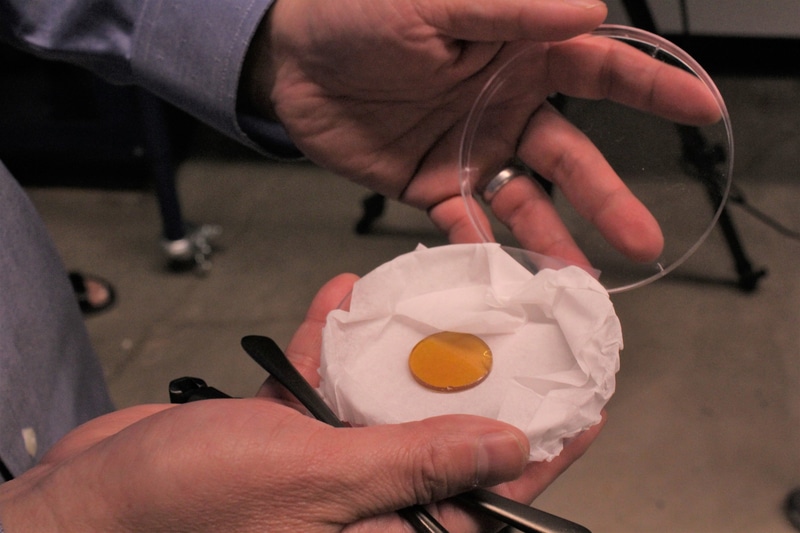

A sample of the polymer material. (Image credit: Mikayla Mace)

A sample of the polymer material. (Image credit: Mikayla Mace)

Since then, researchers under the guidance of Pyun have refined the material and developed the new generation of lenses. The sulfur-based polymer plastic, made from waste obtained through fossil fuel refining, is extremely useful for windows, lenses, and other devices that require infrared (IR) light transmission, which makes heat visible.

IR imaging technology is already used extensively for military applications such as night vision and heat-seeking missiles. But for consumers and the transportation sector, cost limits high-volume production of this technology.

Jeffrey Pyun, Materials Scientist, University of Arizona

Pyun is a professor in the Department of Chemistry and Biochemistry, who leads the team that produced the polymer.

Norwood, a professor in the James C. Wyant College of Optical Sciences, stated that such new lens material could make sensor devices and IR cameras easily available to consumers. Prospective consumer applications include less-expensive autonomous vehicles and in-home thermal imaging for fire protection or safety.

The new polymers are robust and highly resistant to temperature compared to the first-generation sulfur plastic produced in 2014, which was transparent to mid-IR wavelengths. These new lenses are transparent to a broad spectral window, expanding into the long-wave IR, and are far less costly than the existing industry standard of metal-based lenses made of germanium, which is a costly, rare, heavy, and harmful material.

Owing to the several drawbacks of germanium, Tristan Kleine, a graduate student in Pyun’s lab and first author on the study, found a sulfur-based plastic as an interesting alternative. It is, however, very difficult to develop IR-transparent plastics.

The elements that could lead to useful optical properties, like sulfur-sulfur bonds, also include the temperature resistance and strength of the material. Kleine said that, furthermore, the addition of more organic molecules to provide the material strength led to reduced transparency, as nearly all organic molecules absorb IR light.

To overcome this issue, Kleine collaborated with Meghan Talbot, a chemistry graduate student, and Dennis Lichtenberger, a chemistry and biochemistry professor, to use computational simulations to develop organic molecules that were not IR-absorbing and estimated transparency of candidate materials.

It could have taken years to test these materials in the laboratory, but we were able to greatly accelerate new materials design using this method.

Tristan Kleine, Study First Author and Graduate Student, University of Arizona

Germanium needs temperatures over 1700 °F to melt and shape. However, due to its chemical composition, the sulfur polymer lenses can be shaped at a considerably lower temperature.

“A major advantage of these new sulfur-based plastics is the ability to readily process these materials at much lower temperatures than germanium into useful optical elements for cameras or sensors, while still maintaining good thermomechanical properties to prevent cracking or scratches,” remarked Pyun. “This new material has just checked so many boxes we couldn’t before.”

Norwood added, “Its reliability is essentially equivalent to optical polymers that are routinely used for eyeglasses.”

The researchers along with Tech Launch Arizona try converting the study into a feasible technology.

Humans light up like a Christmas tree in IR. So, as we think about the Internet of Things and human-machine interfaces, the use of IR sensors is going to be a really important way to detect human behavior and activity.

Jeffrey Pyun, Materials Scientist, University of Arizona

Scientists from the University of Delaware and Seoul National University also contributed to the study, which was reported in Angewandte Chemie on October 29th, 2019.