Seika Machinery, Inc., a leading provider of advanced machinery, materials and engineering services, today announced plans to exhibit in Booth #307 at SMTA International, scheduled to take place Oct. 16-17, 2018 at the Donald Stephens Convention Center in Rosemont, IL. Seika will showcase a complete line up of leading-edge equipment, including the latest models from McDry, Unitech, Sayaka and MALCOM.

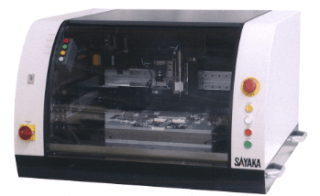

The Sayaka SAM-CT23S tabletop router with color CCD camera offers automatic alignment compensation with fiducial marks and automatic program change with QR code. With AC115V operation, no compressed air is necessary. Advanced image processing software allows easy programming and CAD based offline programming.

The new McDry DXU-1001A high performance dry cabinet maintains one percent RH levels. All McDry ultra-low humidity storage cabinets conform to IPC/JEDEC J-STD 033D and IPC 1601 Standards. Additionally, the ESD safe design adheres to the IEC-61340-5-1 (ESD) Standard. McDry cabinets dehumidify ICs to prevent micro-cracking and are an alternative to baking, MBBs and nitrogen storage.

Seika also will highlight the UNITECH UC-250M-CV PCB Board Cleaner. The UC-250M-CV takes all the features of the UC-250M and adds a dual cleaning feature using a combination of a brush roller with the silicone/adhesive cleaning rollers. The combination dual dust removal system assures better results than a single brush or adhesive roller system.

The MALCOM RCX Series Modular Reflow Oven Profiling System offers complete profiling of reflow ovens, including oven temperature, video imaging, O2 concentration and convection air velocity. It verifies that ovens are performing at optimal conditions, and enables users to troubleshoot problem areas.

The MALCOM PCU-02V Spiral Viscometer is designed for expensive material testing and analysis by obtaining the viscosity characteristics with only a 0.2cc sample. MALCOM’s unique Spiral Sensor provides continuous measurement of non-newtonian fluids with good repeatability.

The MALCOM SPS-2000 Paste Mixer features high-speed mixing capabilities (approx. 1000RPM), resulting in shorter mixing times. The mixer can be programmed to automatically stop at a specified mixing time or paste temperature. The system’s temperature monitoring function allows the user to verify the paste's optimum temperature.