To keep up with growing demand, and diversifying product requirements, LASER COMPONENTS‘ partner Holo/OR are pleased to announce a number of new developments to their production facility. As well as general refurbishments to maintain consistent high quality production, new machines have also been installed.

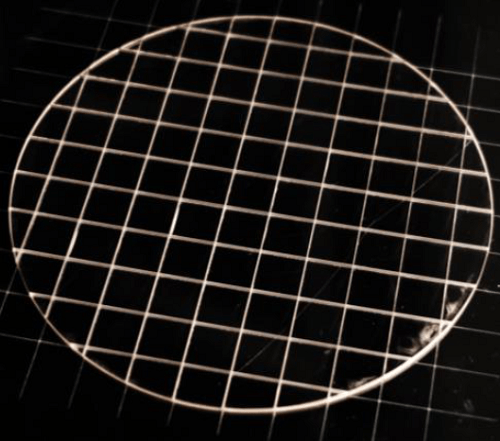

It is now possible to produce diffractive optical elements on 150mm diameter wafers. Not only does this allow for producing DOEs of much larger diameter than previously offered, but also significantly improves volume production capacity and allows further cost reduction for large quantities. For example, a single 150mm diameter wafer may be cut into 69 14x14mm optics.

Image Credits: Laser Components

Image Credits: Laser Components

In addition, Holo/OR have developed a new polymer on glass DOE production capability. Based on glass-like polymers with relatively high laser damage thresholds and good temperature stability, these parts offer significant cost savings and shorter lead times than fused silica in volumes of 100 units or more.

For more in formation please visit: https://www.lasercomponents.com/uk/optics/optical-components/diff ractive-opticalelements/