Jan 18 2018

In a first ever attempt, scientists have demonstrated that an optical fiber, with thickness analogous to that of a strand of human hair, can be used to develop microscopic structures by means of laser-based 3D printing.

The inventive strategy may be, in the future, used in combination with an endoscope to directly insert minute biocompatible structures into tissue in the body. This potential can provide innovative methods to repair tissue damage.

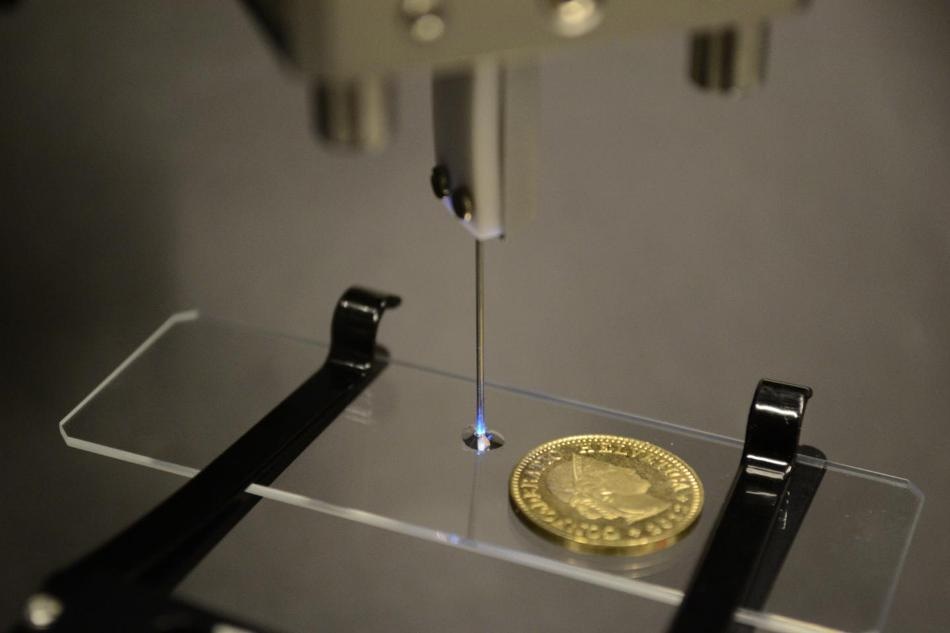

Researchers used an optical fiber housed inside the needle pictured to deliver light for 3-D printing microstructures. The light selectively hardens volumes inside the droplet of photopolymer on the glass slide. The new system could one day allow 3-D printing inside the body. (Image credit: Damien Loterie and Paul Delrot, École Polytechnique Fédérale de Lausanne.)

Researchers used an optical fiber housed inside the needle pictured to deliver light for 3-D printing microstructures. The light selectively hardens volumes inside the droplet of photopolymer on the glass slide. The new system could one day allow 3-D printing inside the body. (Image credit: Damien Loterie and Paul Delrot, École Polytechnique Fédérale de Lausanne.)

“With further development our technique could enable endoscopic microfabrication tools that would be valuable during surgery,” stated Paul Delrot, leader of the research team, from École Polytechnique Fédérale de Lausanne, Switzerland. “These tools could be used to print micro- or nano-scale 3D structures that facilitate the adhesion and growth of cells to create engineered tissue that restores damaged tissues.”

The team has demonstrated that their new strategy can develop microstructures with a 1.0-mm lateral, or side-to-side, and 21.5-mm axial, or depth, printing resolution. The findings of the study have been reported in Optics Express, a journal published by The Optical Society (OSA). Despite the fact that these microstructures were developed on a microscope slide, the strategy can be helpful for analyzing the way cells interact with different microstructures in animal models, which will open the door for endoscopic printing in humans.

In order to develop the microstructures, the team dipped an optical fiber’s end into a liquid called as photopolymer that gets solidified, or cured, upon being illuminated with a particular color of light. Using the optical fiber, the researchers distributed and digitally focused laser light point-by-point into the liquid to develop a three-dimensional microstructure.

If delicate details are printed onto large parts, the innovative ultra-compact microfabrication tool can prove to be a practical supplement to prevalent, commercially accessible 3D printers used for various applications such as rapid prototyping and developing personalized medical devices. “By using one printer head with a low resolution for the bulk parts and our device as a secondary printer head for the fine details, multi-resolution additive manufacturing could be achieved,” stated Delrot.

Simplifying the Setup

Prevalent laser-based microfabrication methods are dependent on a non-linear optical phenomenon known as two-photon photopolymerization to selectively cure a volume deep within a liquid photosensitive material. These methods are challenging to be applied for biomedical use because two-photon photopolymerization mandates complicated and high-cost lasers that deliver very short pulses, and also heavy optical systems to emit the light.

Our group has expertise in manipulating and shaping light through optical fibers, which led us to think that microstructures could be printed with a compact system. In addition, to make the system more affordable, we took advantage of a photopolymer with a nonlinear dose response. This can work with a simple continuous-wave laser, so expensive pulsed lasers were not required.

Paul Delrot

In order to selectively cure a chosen volume of material, the team made the most of a chemical phenomenon in which solidification takes place only above a specific threshold in light intensity. The team performed an in-depth analysis of the light scanning parameters and the behavior of the photopolymer, and found out the optimum parameters for applying this chemical phenomenon to print microstructures by means of a low-cost, low-power laser with continuous, and not pulsed, emission.

For developing hollow and solid microstructures, the team used an organic polymer precursor doped with photoinitiator developed by using off-the-shelf chemical components. They focused the output of a continuous-wave laser discharging light at 488-nm wavelength, visible-wavelength light that is prospectively safe for cells, through an optical fiber adequately small to fit into a syringe. The used a strategy called wavefront shaping to focus the light into the photopolymer such that only a small 3D point was cured. A calibration step carried out before microfabrication enabled them to digitally focus and scan laser light into the ultra-thin optical fiber without the need for moving it.

Compared to two-photon photopolymerization state-of-the-art systems, our device has a coarser printing resolution, however, it is potentially sufficient to study cellular interactions and does not require bulky optical systems nor expensive pulsed lasers. Since our approach doesn’t require complex optical components, it could be adapted to use with current endoscopic systems.

Paul Delro

Moving Toward Clinical Use

The team is striving to create biocompatible photopolymers and a concise photopolymer delivery system, which is inevitable before applying the method for humans. It also requires a higher scanning speed; however, in cases in which the size of the instrument is not crucial, the drawback can be overcome by making use of a commercial endoscope in the place of the ultra-thin fiber. Eventually, a method for finalizing and post-processing the printed structure within the body is needed to develop microstructures with biomedical functions.

“Our work shows that 3D microfabrication can be achieved with techniques other than focusing a high-power femtosecond pulsed laser,” stated Delrot. “Using less complex lasers or light sources will make additive manufacturing more accessible and create new opportunities of applications such as the one we demonstrated.”