Sep 7 2017

ETH Zurich Chemical Engineers have, for the very first time, successfully produced ultra-pure green light. The new light-emitting diode will make room for visibly enhanced color quality in a new generation of ultra-high definition displays for smartphones and TVs.

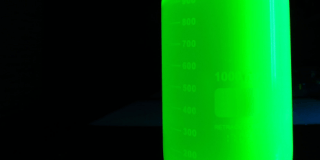

Chih-Jen Shih is extremely satisfied with his innovation, “To date, no one has succeeded in producing green light as pure as we have,” says the Professor of Chemical Engineering in his laboratory at the Hönggerberg campus. He focuses on an ultra-slim, bendable light-emitting diode (LED), which is capable of displaying the three letters “ETH” in a fine hue of bright green.

ETH chemical engineers have produced the purest green with a light-emitting diode. This is good news for TV displays. (Image: Sudhir Kumar / ETH Zurich)

ETH chemical engineers have produced the purest green with a light-emitting diode. This is good news for TV displays. (Image: Sudhir Kumar / ETH Zurich)

Shih’s progress is important, especially in terms of the future generation of ultra-high resolution displays employed for smartphones and TVs. First, electronic devices should be capable of producing ultra-pure green, blue and red light in order to improve the latest generation of displays to show images that are sharper, clearer, richer in detail and with a more refined variety of colors. For the most part, this has already been possible for blue and red light; green light, however, has until now reached the limits of technology.

This is chiefly because of human perception, since the eye is capable of distinguishing between more intermediary green hues than blue or red ones.

This makes the technical production of ultra-pure green very complex, which creates challenges for us when it comes to developing technology and materials.

Sudhir Kumar, Co-lead Author of the report

Up to 99 percent ultra-pure green

The level of progress made by Shih’s ultra-green light in the development of the next generation of displays can be clearly understood by referring to the Rec.2020 standard. The technical requirements for ultra-high resolution (called “Ultra HD”) displays are defined by the international standard, which also offers a framework for additional research and development. The requirements also cover an enhancement in color quality visible to the naked eye. The color scale that can be produced by a display is provided by the standard, thus offering a wider range of color hues.

Ultra-pure green plays a vital role in extending the color range, or gamut. Ultimately, new hues are developed via the technical mixture of three base colors: green, blue and red. When the base colors are purer, a screen will be able to display a broader range of hues. Shih’s new LED is in line with 97 to 99% of the Rec. 2020 standard. By comparison, the purest color TV displays presently available on the market cover on average only 73.11 to 77.72%; none go beyond 80%.

Inexpensive, producible LED technology

Wendelin Stark, ETH Professor of Functional Materials Engineering along with Researchers from South Korea and Taiwan also contributed to the project results, which are featured in the scientific journal Nano Letters. Shih made a breakthrough in terms of the results, and also in the method and the material. He and his colleagues have efficiently produced an ultra-thin, bendable light-emitting diode capable of emitting pure green light by employing simple room-temperature processes.

Shih explains that this is the second aspect of his innovation and is at least equally vital, because until now high-temperature processes were needed for producing pure light with LED technology.

Because we were able to realise the entire process at room temperature, we’ve opened up opportunities for the simple, low-cost industrial production of ultra-green light-emitting diodes in the future.

Jakub Jagielski, Co-lead Author of the report

To be more specific, Shih and his team employed nanomaterials to bring about further developments in the LED technology. A light-emitting diode generally contains a semiconductor crystal capable of converting electrical current passed through it into radiant light. Generally, the raw material is indium gallium nitride (InGaN); however, this material does not contain the suitable properties for production of ultra-pure green light. Thus, Shih’s team instead made use of perovskite, which is a material that is also used for manufacturing solar cells and capable of converting electricity into light in a comparatively efficient manner. It is also cost-effective and enables the manufacturing process to be fast and simple. Shih says that it takes only half an hour to chemically clean perovskite and make it ready for use.

Shih’s light-emitting diode has a tiny 4.8 nm thick perovskite material. This is a vital factor, since the color quality relies on the form and thickness of the nanocrystal used. The crystals should not be any thinner or thicker in order to reach the desired pure green. These ultra-thin, flexible light-emitting diodes are as bendable as a sheet of paper. They can thus be produced in a cost-effective and speedy manner by using the existing roll-to-roll process for example. According to Shih, this will also benefit industrial production in the future.

Next step: improve efficiency

It will certainly take some time to see the first industrial application of ultra-green light-emitting diodes. Next, Shih will have to enhance the efficiency. Today, his LED operates at 3% efficiency when converting electricity into light; in comparison, TV screens that are presently available in the market have efficiency values of 5 to 10%. Shih is expecting the next version to be 6 to 7% more efficient. He also sees the possibility to bring about advancements in the lifespan of his light-emitting diode. Presently, it illuminates for around two hours, while screens that are commercially available should work for several years.