Feb 2 2017

(CREDIT - Yuge Huang and Ruidong Zhu, CREOL, The College of Optics and Photonics, University of Central Florida)

(CREDIT - Yuge Huang and Ruidong Zhu, CREOL, The College of Optics and Photonics, University of Central Florida)

A new blue-phase liquid crystal that could enable computer screens, televisions and several other displays that pack additional pixels into the same space while simultaneously decreasing the power required to run the device has been developed by an international team of researchers.

Today’s Apple Retina displays have a resolution density of about 500 pixels per inch. With our new technology, a resolution density of 1500 pixels per inch could be achieved on the same sized screen. This is especially attractive for virtual reality headsets or augmented reality technology, which must achieve high resolution in a small screen to look sharp when placed close to our eyes.

Shin-Tson Wu, University of Central Florida’s College of Optics and Photonics (CREOL)

Even though a demonstration of the first blue-phase LCD prototype was carried out by Samsung in 2008, the technology has still not entered into production because of problems related to slow capacitor charging time and high operation voltage. Wu’s research team dealt with these issues by working with collaborators from liquid crystal manufacturer JNC Petrochemical Corporation in Japan and display manufacturer AU Optronics Corporation in Taiwan.

Optical Materials Express, a journal from The Optical Society (OSA), has published a report presented by the researchers about how the combination of the new liquid crystal with a particular performance-improving electrode structure can attain light transmittance of 74% together with an operation voltage of 15 volts per pixel – operational levels capable of finally making field-sequential color displays practical for product development.

Field-sequential color displays can be used to achieve the smaller pixels needed to increase resolution density. This is important because the resolution density of today’s technology is almost at its limit.

Yuge Huang, first author of the paper

How it Works

LCD screens that are currently available are made up of a thin layer of nematic liquid crystal wheremodulation of the incoming white LED backlight takes place. The required voltage that monitors light transmission in every single pixel is delivered by thin-film transistors.

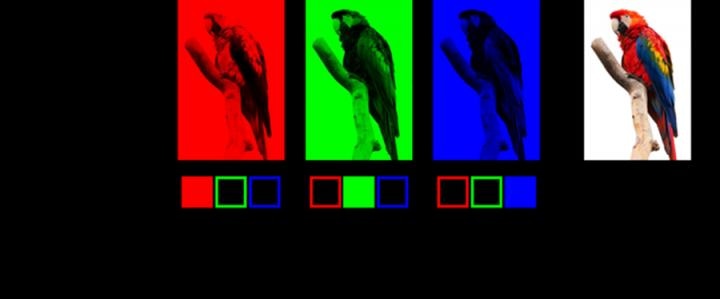

The LCD subpixels comprise of red, green and blue filters that are used in combination to develop a wide range of colors to the human eye. All three colors combined together develop the color white.

It is possible to control or switch the blue-phase liquid crystal about 10 times faster than the nematic type. This sub-millisecond response time permits each LED color (red, green and blue) to be sent through the liquid crystal at different times and prevents the use of color filters. Switching of the LED colors take place extremely fast such that human eyes can combine blue, green and red form white.

With color filters, the red, green and blue light are all generated at the same time. However, with blue-phase liquid crystal we can use one subpixel to make all three colors, but at different times. This converts space into time, a space-saving configuration of two-thirds, which triples the resolution density.

Shin-Tson Wu, University of Central Florida’s College of Optics and Photonics (CREOL)

Additionally, the blue-phase liquid crystal triples the optical efficiency as the light does not have to travel through color filters, which restrict transmittance to about 30%. Another key benefit is that the displayed color turns out be a lot more vivid as it comes directly from red, green and blue LEDs, which prevents the color crosstalk that takes place with standard color filters.

Wu’s team collaborated with JNC in order to reduce the blue-phase liquid crystal’s dielectric constant to a minimally acceptable range, reducing the transistor charging time and attaining submillisecond optical response time. However, every single pixel still required a somewhat slightly higher voltage than a single transistor could provide.

To overcome this issue, the researchers used a protruded electrode structure that allows the electric field to pass through the liquid crystal more deeply. This indeed reduced the voltage required to drive each pixel while also maintaining a high light transmittance.

“We achieved an operational voltage low enough to allow each pixel to be driven by a single transistor while also achieving a response time of less than 1 millisecond,” said Haiwei Chen, a doctoral student in Wu’s lab. “This delicate balance between operational voltage and response time is key for enabling field sequential color displays.”

Making a Prototype

Now that we have shown that combining the blue-phase liquid crystal with the protruded electron structure is feasible, the next step is for industry to combine them into a working prototype. Our partner AU Optronics has extensive experience in manufacturing the protruded electrode structure and is in a good position to produce this prototype.

Shin-Tson Wu, University of Central Florida’s College of Optics and Photonics (CREOL)

Wu predicts the possibility of developing a working prototype in the following year. AU Optronics already has a prototype that uses the protruded electrodes, and this indeed highlights that it will only be a matter of working with JNC to obtain the new material into that prototype.