Oct 12 2016

A team of Shanghai Jiao Tong University researchers has used the shape of cicada wings as a template to create antireflective structures fabricated with one of the most intriguing semiconductor materials, titanium dioxide (TiO2). The antireflective structures they produced are capable of suppressing visible light -- 450 to 750 nanometers -- at different angles of incidence.

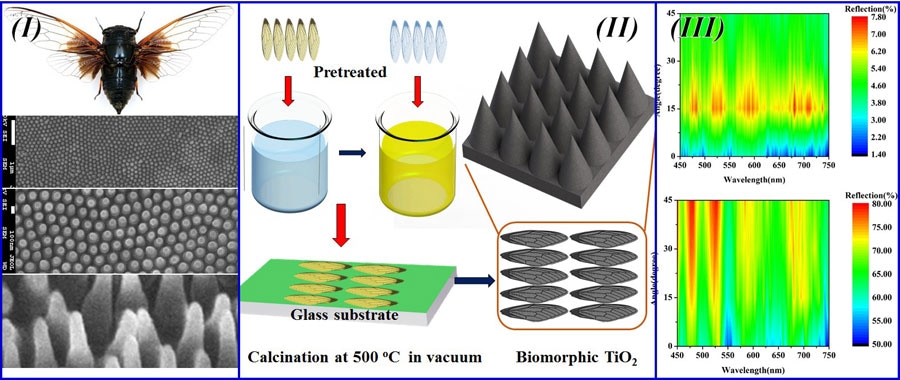

I. Photograph and scanning electron microscope characterizations of a black cicada wing (Cryptympana atrata Fabricius). II. Synthesis process of biomorphic TiO2 with ordered nano-nipple array structures. III. Counter map angle-dependent antireflection of biomorphic TiO2 and non-templated TiO2, respectively. CREDIT: Shanghai Jiao Tong University

I. Photograph and scanning electron microscope characterizations of a black cicada wing (Cryptympana atrata Fabricius). II. Synthesis process of biomorphic TiO2 with ordered nano-nipple array structures. III. Counter map angle-dependent antireflection of biomorphic TiO2 and non-templated TiO2, respectively. CREDIT: Shanghai Jiao Tong University

Why cicada wings? The surfaces of the insect’s wings are composed of highly ordered, tiny vertical “nano-nipple” arrays, according to the researchers. As they report this week in Applied Physics Letters, from AIP Publishing, the resulting biomorphic TiO2 surface they created with antireflective structures shows a significant decrease in reflectivity.

“This can be attributed to an optimally graded refractive index profile between air and the TiO2 via antireflective structures on the surface,” explained Wang Zhang, associate professor at State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University in China.

Small spaces between the ordered nano-antireflective structures “can be thought of as a light-transfer path that let incident light rays into the interior surface of the biomorphic TiO2 -- allowing the incident light rays to completely enter the structure,” Zhang continued. “The multiple reflective and scattering effects of the antireflective structures prevented the incident light from returning to the outside atmosphere.”

Significantly, the team’s work relies on “a simple and low-cost sol-gel (wet chemical) method to fabricate biomorphic TiO2 with precise subwavelength antireflective surfaces,” Zhang pointed out. “The TiO2 was a purely anatase phase (a mineral form of TiO2), which has unique antireflective surfaces. This led to an optimally graded refractive index and, ultimately, to angle-dependent antireflective properties within the visible light range.”

In terms of applications, the team’s biomorphic TiO2 antireflective structures “show great potential for photovoltaic devices such as solar cells,” Zhang said. “We expect our work to inspire and motivate engineers to develop antireflective surfaces with unique structures for various practical applications.”

Even after high calcination at 500 C, the antireflective structures retain their morphology and high-performance antireflection properties. These qualities should enable the coatings to withstand harsh environments and make them suitable for long-term applications.

In the future, the team plans “to reduce the optical losses in solar cells by using materials with a higher refractive index such as tantalum pentoxide or any other semiconductor materials,” Zhang said.