Aug 17 2016

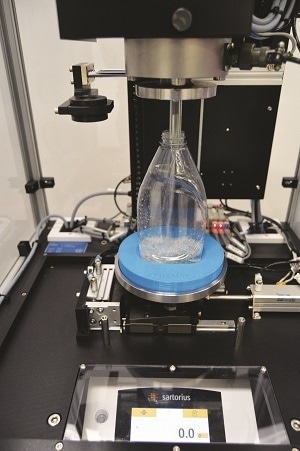

The system showcases a single operation Top Load & Volume Test to the plastic bottle market.

Once the bottle is loaded by the operator all functions can be carried out in sequence without the need for operator interference to move the bottle between tests. The gauge will allow bottle manufacturers and fillers the ability to verify mold designs, dimensions and geometry, providing the customer with a solution to carry out precise volumetric measurement in accordance with export laws and safeguarding bottle strength during transport for stacking and palletizing.

The key benefit of the B304 Top Load & Volume Gauge is the ability to perform two tests in one system. By combining the two tests (Top Load and Volume), it negates the need for operator intervention thus eradicating laborious manual inspection and saving time.

Carrying out time-consuming manual volume tests often results in inaccuracies. The average time to perform a manual volume test is approximately 8-10 minutes per bottle with the quality of results being susceptible to human error. In stark contrast the Torus B304 Top Load & Volume Gauge delivers a fast, integrated, high quality test with proven technology. The Top Load results are traceable to UKAS standards and the system adheres to ASTM D2659 standard test method for Column Crush properties of blown thermoplastic containers.

Spencer Whale, Technical Sales Manager for Plastic Packaging at Torus Measurement Systems commented on the B304. ‘The gauge is simple to operate and outputs a variety of reports. A particular favorite is the Graphical Batch Report which displays the part on part signature of Top Load strength thus helping to determine variations in bottles between cavities/production.’

The user simply selects the part and test mode, loads the bottle into a centralized location and waits for the results. Standard selectable measurement features of the gauge are; brim-full volume, fill height volume, dry top load force, wet top load force (filled bottle), empty bottle weight and bottle deflection point.

An example of the B304 volume test would be, recording the empty bottle weight, filling the bottle to brim-full or fill height set point, measuring the weight of the filled bottle and automatically calculating the volume using the weight and temperature data.

The modern design utilizes interactive touch screen with Windows® based software, outputting data results either numerically or graphically, giving the user an enhanced visual representation of the bottle characteristics. Exported data can be delivered in either CSV file or SPC package formats to suit the customer.

B304 Top Load & Volume Gauges are currently installed in large industry leading bottle manufacturers. Due to the enclosed self-contained cabinet the system is suitable for shop-floor or laboratory environments and is commonly used in research & development or production. Torus gauges are installed around the world and are fully supported by a global dedicated service team.