Scientists from the University of Illinois at Urbana-Champaign have found a new method to make green LEDs with enhanced brightness and efficiency.

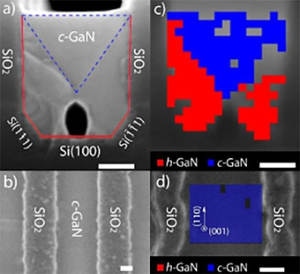

A new method of cubic phase synthesis: Hexagonal-to-cubic phase transformation. The scale bars represent 100nm in all images. (a) Cross sectional and (b) Top-view SEM images of cubic GaN grown on U-grooved Si(100). (c) Cross sectional and (d) Top-view EBSD images of cubic GaN grown on U-grooved Si (100), showing cubic GaN in blue, and hexagonal GaN in red. (Credit: University of Illinois)

A new method of cubic phase synthesis: Hexagonal-to-cubic phase transformation. The scale bars represent 100nm in all images. (a) Cross sectional and (b) Top-view SEM images of cubic GaN grown on U-grooved Si(100). (c) Cross sectional and (d) Top-view EBSD images of cubic GaN grown on U-grooved Si (100), showing cubic GaN in blue, and hexagonal GaN in red. (Credit: University of Illinois)

They created gallium nitride (GaN) cubic crystals grown on a silicon substrate, capable of generating powerful green light for enhanced solid-state lighting by making use of an industry-standard semiconductor growth method.

Normally, GaN is produced in either hexagonal or cubic crystal structures. Hexagonal GaN is thermodynamically steady and is considered to be the more standard form of the semiconductor.

However, this structure is prone to the polarization phenomenon, where the positively charged holes and negatively charged electrons are separated by an internal electric field, which prevents them from combining and consequently diminishes the efficiency of the light output.

So far, the investigators were only able to produce cubic GaN by leveraging molecular beam epitaxy, a very costly and slow technique to grow crystals compared to the generally employed metal-organic chemical vapor deposition (MOCVD) technique that Bayram used.

Can Bayram, an assistant professor of electrical and computer engineering at Illinois, first began investigating this material while at IBM T.J. Watson Research Center several years ago:

This work is very revolutionary, as it paves the way for novel green wavelength emitters that can target advanced solid-state lighting on a scalable CMOS-silicon platform by exploiting the new material, cubic gallium nitride.

The union of solid-state lighting with sensing (e.g. detection) and networking (e.g. communication) to enable smart (i.e. responsive and adaptive) visible lighting, is further poised to revolutionize how we utilize light.

And CMOS-compatible LEDs can facilitate fast, efficient, low-power, and multi-functional technology solutions with less of a footprint and at an ever more affordable device price point for these applications.

Bayram and Richard Liu, a graduate student, produced the cubic GaN by leveraging lithography and isotropic etching in order to develop a U-shaped groove on Si (100). The non-conducting layer served as a border that makes the hexagonal material turn into cubic form.

“Our cubic GaN does not have an internal electric field that separates the charge carriers—the holes and electrons,” explained Liu. “So, they can overlap and when that happens, the electrons and holes combine faster to produce light.”

Bayram and Liu believe that their cubic GaN technique will pave the way to make LEDs free from a detrimental phenomenon known as "droop" that inundated the LED business for several years. The light-emission efficiency for green, blue, or ultra-violet LEDs drops when additional current is supplied, which is described as "droop."

“Our work suggests polarization plays an important role in the droop, pushing the electrons and holes away from each other, particularly under low-injection current densities,” said Liu, who was the lead author of the paper, “Maximizing Cubic Phase Gallium Nitride Surface Coverage on Nano-patterned Silicon (100)”, appearing in Applied Physics Letters.

“Being polarization-free, cubic LEDs can have thicker active layers eliminating the reduced electron-hole overlap and current overflow. There are recent efforts by other groups to produce cubic GaN LEDs, but they are made on silicon carbide substrates, which is very expensive and have two orders of magnitude higher defectivity compared to our cubic GaN on silicon.”

Better performing green LEDs will bring in new opportunities for LEDs in general solid-state lighting. For instance, these green LEDs will save energy by producing white light through a color mixing technique. They can also be for various applications including underwater communications, ultra-parallel LED connectivity via phosphor-free green LEDs, and biotechnology such as migraine treatment and optogenetics.

Besides its use in green LEDs, Bayram’s cubic GaN could one day replace silicon to produce power electronic gadgets used in electronic substations and laptop power adapters. It could also replace mercury lamps to produce ultra-violet LEDs that purify water.

Bayram and Liu conducted their research in the Micro and Nanotechnology Lab (MNTL) at Illinois.