Indium Corporation will feature Heat-Spring®, a compressible, recyclable, metal thermal interface material, at Strategies in Light, Feb. 24-26 in Las Vegas, Nev.

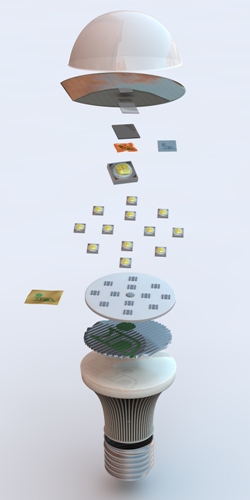

Indium_LED Bulb Stackup

Indium_LED Bulb Stackup

The use of high-power LEDs is growing exponentially due to light quality, energy efficiency, and reliability. These attributes are directly related to design and assembly methods and materials.

Indium Corporation’s Heat-Spring is a compressible interface material that provides86W/mKof thermal conductivity using a pressure range of only 35 to 100+ psi. Heat-Spring offers superior conductivity and ease of use as compared to thermal grease alternatives. In addition, Heat-Spring will not bake out or pump out, optimizing long-term performance consistency and eliminatingthe rework process.

Heat-Spring is reclaimable and recyclable, and is packagedin custom trays or tape & reel.

Heat-Spring is just one of a wide range of Indium Corporation materialsfor the LED assembly industry, from PCB assembly to die-attach totechnology-enabling TIM, that combines superior performance with ease of placement. This reduces cost, increases first-pass yield, reduces field failures, and contributes to the optimization of profit.

For more information on Heat-Spring, visit www.indium.com/thermal-interface-materials/heat-spring or visit Indium Corporation at booth 623.

Indium Corporation is a premier materials manufacturer and supplier to the global electronics, semiconductor, solar, thin-film, and thermal management markets. Products include solders and fluxes; brazes; thermal interface materials; sputtering targets; indium, gallium, germanium, and tin metals and inorganic compounds; and NanoFoil®. Founded in 1934, Indium has global technical support and factories located in China, Malaysia, Singapore, South Korea, the United Kingdom, and the USA.

For more information about Indium Corporation, visit www.indium.com or email [email protected].