IDS Imaging Development Systems, a global leader in medical and machine vision, has entered the emerging three-dimensional vision market with a groundbreaking new stereo 3D camera: the Ensenso™ N10, introduced last week at the VISION 2012 exhibition in Stuttgart, Germany.

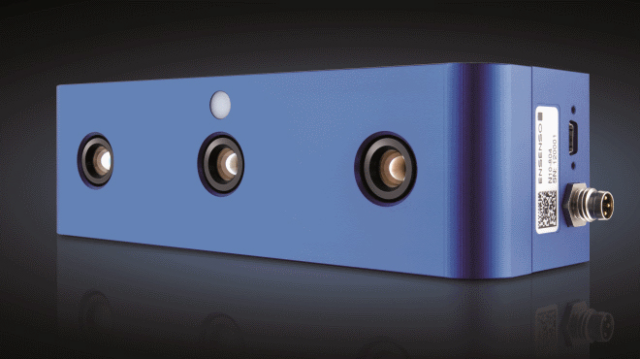

Ensenso N10 Stereo 3D Machine Vision Camera

Ensenso N10 Stereo 3D Machine Vision Camera

The Ensenso™ N10 is fitted with two global shutter CMOS sensors and a pattern projector that projects a static, high-contrast texture onto the object being captured, adding structures that are not visible or are only faintly visible to the human eye. Combined with a "semi-global matching" image comparison algorithm, the result is that nearly all surfaces within the field of vision are captured. This technology also works in multi-camera operations, as well as for capturing unstructured surfaces.

Because of its ease of installation and flexible USB 2.0 interface, the Ensenso N10 camera is suitable for a wide range of vision applications where 2D is not enough. However, medical engineering, robotics and gripping technology, logistics, completeness checking, rapid volume measurement, as well as measurement technology and safety engineering benefit particularly from the innovative camera.

With a refresh rate of 30 frames per second, the Ensenso N10 can be used completely in-line, plus is an excellent solution in 100% inspections. It is optimized for working distances of 280 mm to 1400 mm and available in configurations for variable fields of view. Unlike other 3D recording procedures, the camera can capture both static or moving objects at up to 30 frames per second. Image resolution is 752 x 480 pixel (WVGA).

INDUSTRIAL DESIGN

Featuring a sturdy aluminum housing that measures only 150 x 45 x 45 mm, the Ensenso N10 is qualified for space-sensitive industrial environments, including mounting on mobile robot heads. Its rugged design is underscored by a lockable 3-pin M8 sensor/actuator connector with GPIOs for 12-24 V hardware trigger input and output as well as a lockable USB cable.

SOFTWARE INCLUDED

The comprehensive software package, which is included free of charge, has an MVTec HALCON interface and an object-oriented API (C++), thus allowing optimum integration into existing systems.

Because the Ensenso N10 is factory calibrated, installation for 3D surface matching using the MVTec Halcon interface takes less than ten minutes out of the box. Customers can also integrate the camera easily into their own application programs. When working with multiple cameras, the software package enables output of a single 3D point cloud containing the data of all the cameras used, resulting in the capture of the scene synchronously from different sides, thus reducing shadowing effects and extending the field of view.