Dec 5 2012

Vision systems integrator. Olmec-UK, has developed a novel multi-camera, multi-illumination high speed inspection system to check the integrity of the foil seal on the plastic lids that are used to seal a wide range of glass and plastic containers in the food, healthcare and pharmaceutical industries. These foil seals provide an air-tight seal to protect against contamination, humidity, tampering and leakages in order to maintain product freshness and increase shelf life. This type of lid and seal are used on a wide range of products from milk bottles to sauces such as ketchup, powdered drinks and tablet containers.

Foil inspection

Foil inspection

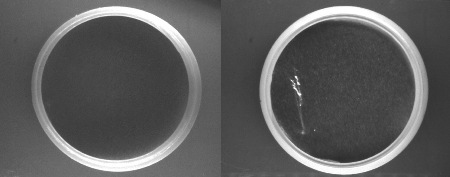

The foil is inspected to make sure that there are no blisters, dents or creases in it and that it has not lifted from the rim before the lid is sent to the induction heated container sealing station. This inspection is a critical part of the quality control process.

The lids are produced with the foil sealed into the lid ready for subsequent sealing to the container. Damage to the foil can occur during transit. The challenges faced in designing a high-speed vision solution included the highly reflective nature of the foil material, the variety of possible defects and their random orientation as well as the depth of the foil inside the lid.

In order to capture all of the defects, the foil needs to be illuminated from different directions and imaged by 3 cameras positioned at different angles to the foil. The lighting runs in a sequence of 3 illumination combinations for each of the three cameras, thus producing nine individual images for each lid inspected. Full frame images are captured using Genie HM 1400 cameras from Teledyne DALSA, allowing the 9 images to be captured for analysis in just 48 milliseconds for high volume inspection.

The new system can be readily integrated into a production line environment, with an air knife mechanism or similar used to fire rejected lids from the line. The system features Olmec’s new modular user-interface for Windows®, which is designed for use by production engineers rather than vision experts. This new interface, which provides multi-level security, allows easy review of images from failed components and can also be set up for remote diagnostics, if required.

Olmec Technical Director, Robert Pounder said: “Olmec is frequently asked to provide solutions of this nature by a wide range of customers who need to integrate vision into their production lines. For this reason, we have very recently developed our ‘Quality Station’ product. This can be configured for a wide range of inspection applications and features an integral transport and reject mechanism. With a footprint of just 1.2 m x 0.7 m, the Quality Station can be easily added to the manufacturing environment to provide in-line inspection.”