Daewon Innost has recently launched the Glaxum LED Array family of Chip-On Board modules. Based on Daewon Innost’s proprietary Nano-Pore Silicon Substrate (NPSS) technology, Glaxum arrays ensure superior thermal dissipation performance, achieving unique thermal impedance of 0.410 C/W. They are constructed based on commercially available 1 W LED chips having increased efficiency.

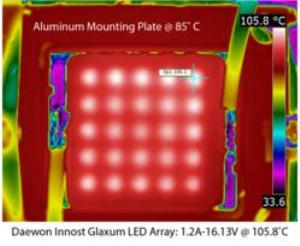

Thermal image of Daewon Innost's Glaxum(TM) module which performs at 0.41°C/Watt

Thermal image of Daewon Innost's Glaxum(TM) module which performs at 0.41°C/Watt

The NPSS technology was developed by Daewon Innost specifically for LED modules for facilitating the achievement of high thermal dissipation performance. The process of developing LED substrate starts by applying semiconductor lithography to silicon wafers, followed by fine pitch interconnection between GaN LED chips, resulting in a pitch spacing of 50 µ in comparison to over 300 µ with existing Metal Core Printed Circuit Board (MCPCB). NPSS provides a number of is advantages over MCPCB which comprise increased levels of integration, excellent thermal performance, and favorable scaling that leads to cost savings with respect to increase in power levels.

According to the CEO of Daewon Innost, Sungyuk ‘Stephen’ Won, being independently tested by an established LED chip supplier, the test results of the company’s LED modules are promising. The results represent the exceeded thermal performance of the high-efficiency chip on board (COB) technology. Glaxum module demonstrates over 120 C cooling efficiency than the earlier high-efficacy COB module. Signifying the thumb industry rule, cooler temperatures will enhance the life for LED arrays.

The Glaxum NPSS modules are being offered in several models ranging from 3.5 to 100 W. Glaxum-MCL-GL-CC-020-002 (cool white) and Glaxum-MCL-GL-WC-020-002 (warm white) are the models with lowest thermal impedance. Glaxum module has a tested voltage and current value of 16.6 V and 1.2 A, respectively.