Stemmer Imaging can now offer a new automatic surface inspection system, based on the patented Trevista image processing system from OBE GmbH & Co KG. Structured diffuse illumination is combined with specialised calculation algorithms within the popular Sherlock machine vision platform from Teledyne DALSA to create a fast automated total inspection solution capable of identifying defects in a range of surfaces from shiny components to diffusely scattering surfaces.

The Trevista process closes the gap between 2D image processing and optical 3D shape recognition by combining the speed of 2D image processing with the precision of 3D recognition to allow a 100% coverage of components, which in turn saves cost. The process filters the image information produced to separate topography and texture into different images. Topographic images allow defects down to a depth of just a few micrometres to be located and classified quickly, reliably and free of interference, while texture images allow differences in brightness on the inspected component to be determined.

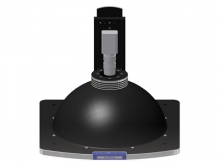

Dome shaped illumination housings are available in 3 different sizes to allow components up to 200 mm to be measured. The housing provides optimum structured and diffuse illumination from different directions and protects the system from ambient light interference. Systems are available with area cameras for the inspection of flat surfaces and line scan cameras for the inspection of cylindrical surfaces. The robust design allows reliable integration into the manufacturing process or into an automatic tester.

The image processing algorithms are integrated into the popular Sherlock advanced machine vision software interface which can be applied to a wide variety of automated inspection applications. Sherlock offers machine vision system professionals extensive tools and capabilities for design, development, debugging, and user administration. The Trevista algorithms can also be implemented through Stemmer Imaging’s own Common Vision Blox imaging toolkit.