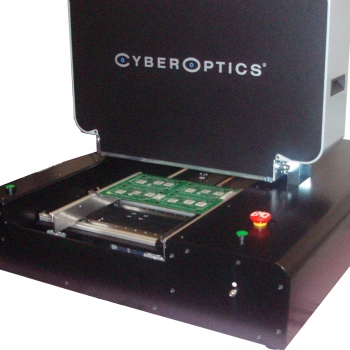

CyberOptics Corporation, a leading SMT inspection solutions provider, will display a prototype version of the new QX100™ AOI Tabletop System alongside its latest inspection technologies in Maxim SMT Technologies’ Booth #1190 in Hall 11 at the upcoming Electronica International Trade Fair, scheduled to take place September 13-16, 2011 at the Pragati Maidan in New Delhi, India.

The QX100™ tabletop system embraces CyberOptics’ unique image acquisition solution using the Strobed Inspection Module (SIM) and is capable of inspecting 01005 components and larger at 100cm²/sec, making it the fastest tabletop system the industry has ever witnessed. The sleek tabletop system is powered by AI2 (Autonomous Image Interpretation), a patented next-generation image analysis technique that exploits the latest advances in processor architecture. AI2 has evolved from the very ideas upon which CyberOptics’ industry-proven SAM technology is rooted. A robust statistical modeling engine forms the core of AI2, providing superior defect detection capabilities, the lowest false call rates and improved clarity of defect identification through Defect Pixel Marking. Designed to fully support unsupervised and semiautomatic model training, AI2 delivers incredibly fast setup times and a streamlined programming workflow. The QX100™ system is ideally designed to match production footprint requirements and fully comply with safety standards.

CyberOptics Display A Prototype Of Tabletop System

CyberOptics Display A Prototype Of Tabletop System

SE350™ 3-D solder paste inspection system is equipped with CyberOptics’ calibration-free 3-D sensor technology to inspect even the most demanding assemblies. The sensor is an integrated assembly designed with no moving parts, eliminating machine-to-machine variation across production lines while offering the lowest cost of ownership in the industry. Leveraging on the development efforts of the SE500™, this system is capable of inspecting pad sizes down to 01005 (150 x 150 ìm).

CyberOptics’ multiple award-winning QX500™ AOI system is innovative in every sense with a unique image acquisition solution — Strobed Inspection Module (SIM), which is designed to deliver high-speed inspection matched with exceptional defect coverage and an extremely low false call rate. Winning its third prestigious award since its launch at NEPCON China 2010 clearly emphasizes the global recognition the QX500™ has gained in terms of technological advancements and superior inspection capability.

The introduction of strobed white lighting in the QX500™ makes it the only AOI system to provide “on-the-fly” area-scanning inspection at an incredible 200 cm²/sec, setting it apart from other conventional AOI systems.

For further information about CyberOptics, visit www.cyberoptics.com.