MIT researchers formulated a technique to develop a complete electronic equipment in liquid. The team showed the technique, known as hydrothermal synthesis, to manufacture working LED array in a microfluidic channel using zinc oxide nanowires.

The researchers did not use costly semiconductor manufacturing techniques and facilities. They used a syringe for pushing the solution using a capillary tube with a width of one-tenth of a millimeter.

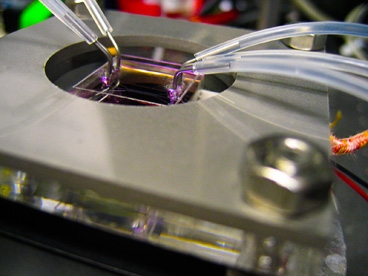

Zinc oxide nanostructures are directly synthesized in parallel microfluidic channels (held by the metal frame) by flowing reactants through the tubing.

Zinc oxide nanostructures are directly synthesized in parallel microfluidic channels (held by the metal frame) by flowing reactants through the tubing.

Researcher Brian Chow stated that there is a connection between the electrical and optical properties and the geometry of nanostructures. The functional properties of nanostructures vary according to the geometry.

The system can impact the nanowires aspect ratio to produce flat plates or long, thin wires. Although there are various means to achieve this, the nanowires can be impacted at high temperatures or with the use of inorganic solvents.

The MIT technique was developed based on the electrostatic properties of the material using zinc oxide as it evolves from a solution. When the ions of various compounds are mixed with the solution, they electrostatically adhere to the sides or the ends of the wire, thus hampering the growth of the wires in all the directions. The zinc oxide material can be used in a wide range of applications such as sensors, batteries and optical equipment. The processing technique used by MIT researchers is suitable for bulk production.

The technique could be implemented with other materials also. Researchers are studying the influence of including titanium dioxide for equipment such as solar cells. As the low-temperature conditions will enable the growth of materials on plastic surfaces, he says, it could be used to develop flexible display panels.