Nov 26 2010

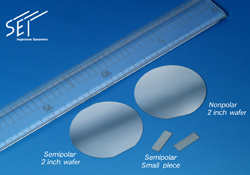

Sumitomo Electric Industries, a Japan-based company, has developed a new production technology, hydride vapor phase epitaxy (HVPE) that allows mass production of 2” diameter nonpolar/semipolar gallium nitride (GaN) substrates for the green lasers.

GaN Substrate

GaN Substrate

The GaN substrate’s c-plane crystal face is utilized for blue or blue-violet semiconductor laser diodes and white LEDs. However, when negatively charged (N) and positively charged gallium (Ga) atoms orient alternately, the c-plane displays robust polarization. This strong polarization reduces the light-emitting efficacy in the green region.

Sumitomo Electric has been developing technologies for nonpolar and semipolar GaN substrates that can enhance the performance of white LEDs and green lasers. The company’s efforts have resulted in developing technologies, which improve the luminous efficiency through reduced piezoelectric effects on the polarized substrates.

Nonpolar and semipolar substrates are developed by diagonally or vertically slicing the GaN crystals along the c-plane. But this technique generates small-sized crystals that reduce the production of high-efficiency LED units. To solve this problem, Sumitomo Electric has developed the HVPE technology for manufacturing 2” substrates.

According to the company, substrates manufactured with this technique displayed a dislocation density of 105.