Sydor Optics, a manufacturer of flat glass optics, has just completed the first half of its acquisition of $4M in double-sided polishing and metrology equipment with the second half of expansion to be completed within the next six months. This investment, coupled with Sydor’s continuous investment in team development and process improvement, allows them to continue their growth while handling their customers’ increasing volume and size demands.

James Sydor, President of Sydor Optics, credits their growth to their willingness to take risks for their customers and modernize their equipment to meet the changing needs created by innovation in industries like entertainment, defense and life sciences. “Although I think we’ve been lucky we’d like to think it’s because we strive to be in step with our customers.

Our products are used daily in products for the military such as heads-up displays and laser protection filters to components in the latest technologies of DNA sequencing to optics used in the production of the latest movies. We tend to stick with our specialty of processing parallel optics using double-sided equipment because it yields exceptional parallelism and transmitted wavefronts.”

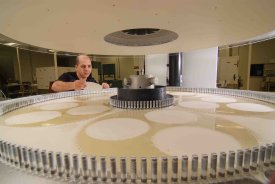

As the largest PR Hoffman equipment owner in the world, Sydor Optics can now double-side grind and polish optics up to 740 mm in diameter. The new equipment includes 11 PR Hoffman 5400 double-sided machines, 2 PR Hoffman 1500 double-sided machines, 2 Haas Mini Mills, a Tropel Flatmaster 200 interferometer and two Zygo interferometers, one with 12” aperture the other with 18” aperture. Two of the PR Hoffman 5400s are their newest model, the Mark IV, which can process large optics.

“Along with our new building this equipment represents our largest investment in growth since the start of the company. This greatly increases our production capacity and sizes of parts we can make”, said Jim Sydor.

In the UK Sydor Optics is represented by Armstrong Optical of Northampton for all of their plano optics components.