LZH (Laser Zentrum Hannover) has developed two laser techniques, which will aid in enhancing traditional welding. The first technique is a GMAW (gas metal-arc welding)-based welding process. LZH stated that by using a laser ray to stabilize and guide the welding process, it can attain two times more speed.

Laser Processing head

Laser Processing head

The gas metal-arc welding method, when added with a laser ray, increases the welding speed to a maximum of 100% for the same depth of welding, and also enhances the welding seam quality. In addition, seams with complex geometry or oscillating seams are easy when laser beam stabilization is used. The new welding process is useful for traditional steels, high strength steels, and aluminum materials. Investment cost is also very less because the laser in the welding process has very less output power.

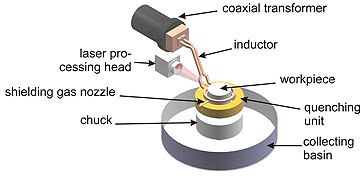

The second technique, developed by the Institute of Electrotechnology and LZH, is an advanced process to harden and weld multiple pieces of heat-treatable steels in a single step. Heat-treatable steels show good endurance strength after the heat treatment process, hence, they are used for construction elements. This process combines laser beam welding and inductive hardening of multi-piece construction elements in a single step. During the process, the construction elements are heated at more than 900°C temperature, and the parts are welded with laser, and quenched.

A processing head has been constructed for the process, which incorporates an inductor, a shielding gas nozzle, a quench shower, and a laser processing head. It combines heating, welding, and hardening processes in a single step. The processing head increased the depth of the welding by 25%, when compared to the construction elements that were not pre-heated. After the welding and hardening process, the construction material’s surface can also be hardened by using an inductor.