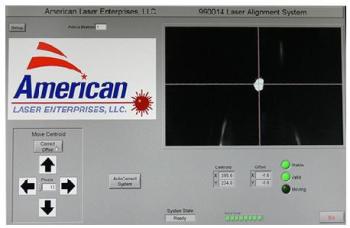

American Laser Enterprises has released the world’s first automated laser alignment system, the A-Las. The new system helps to align difficult laser beam delivery systems in different types of manufacturing processes.

A-Las Automatic Laser Alignment System

A-Las Automatic Laser Alignment System

The company’s Engineers, Keith Jefferies and Don Sprentall had developed the A-Las system for the U.S. Air Force for use in a complex laser paint-stripping system. The A-Las system offers complete solutions for a wide range of laser-beam delivery configurations. Unlike the traditional alignment methods, the A-Las enables users to perform the alignment in very less time.

The laser alignment system offers decreased replacement component inventory and maintenance costs, longer lifespan of delicate optical components, high machine productivity, and no schedule delays. The A-Las increases the machine uptime, removes the need for trial-and-error troubleshooting, and allows one person to diagnose and correct many machines. When compared to the traditional laser alignment procedures, the A-Las system minimizes training costs up to a maximum of 90%.