The surface topography of a material provides information on its mechanical and chemical characteristics, which are crucial in determining its applicability. Atomic force microscopy (AFM) is a robust analytical technique often employed to study the surface topography of the majority of materials. This article provides an overview of AFM and its application in surface-topography imaging.

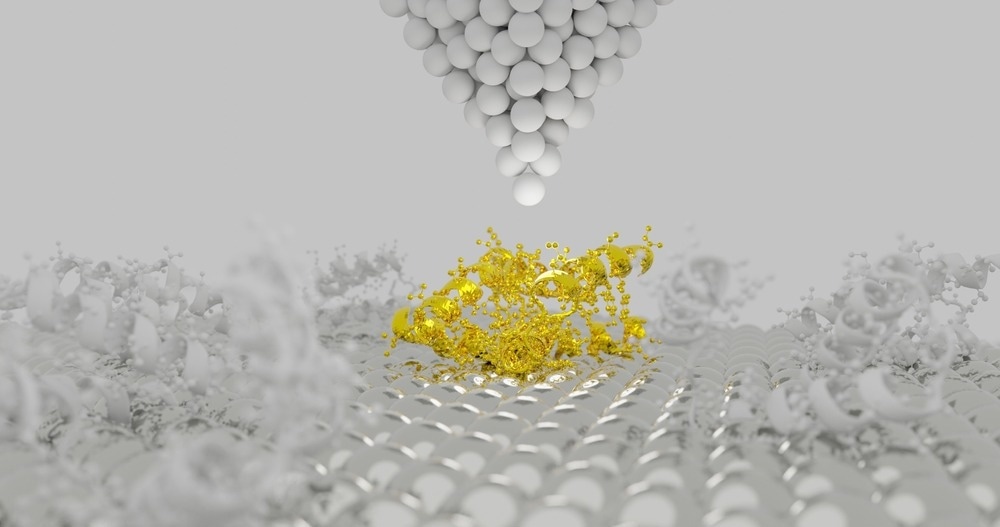

Image Credit: sanjaya viraj bandara/Shutterstock.com

Importance of Surface Topography Imaging

Surface topography is the deviation of a material’s surface from a perfectly flat plane. The topography of the material surface significantly affects its bulk properties. Although surface irregularities occur at the nanoscale level, their impact can be observed through macroscopic measurements. Characterization of surface topography has become crucial in material science, tribology, and other related fields.

There are two ways to measure the topography of a surface:

- Contact method that involves dragging a measurement stylus or profilometer across a surface.

- Non-contact methods that use a feedback mechanism to control the Z-scanner movement.

AFM and its Components

AFM is a robust scanning probe microscope that helps image the surface of a material in three-dimensional (3D) spatial resolution. It aids in determining a sample’s dimensions, physical properties, magnetism, and surface. Additionally, they also help manipulate matter at the nanoscale level, making them suitable for practical applications.

AFM topography images provide substantial information on the surface morphology of a material, for example modes of growth and nucleation, highlight defects, and differentiate between crystalline and amorphous phases.

The components of the AFM instrument are as follows:

- Scanning Probe: The scanning probe consists of a micrometer-scaled cantilever, which has a fixed and a free end. The free end of the cantilever is attached to a nanometer-sized tip. The cantilever serves as a flexible beam and aids in the free movement of the probe.

The properties of a probe, such as its dimensions and material, determine its performance characteristics, including its resolution, stiffness, flexibility, and chemical sensitivity. Hence selecting the right probe is crucial for surface topography imaging.

- Transducers: Electromechanical Transducers facilitate the mechanical motion of the cantilever in AFM. Transducers are composed of piezoelectric ceramic materials whose geometry changes in the presence of an electric field. Hence, the direction and the amount of motion are influenced by the type of piezoelectric materials.

- Force Sensors: These sensors help measure the forces between the surface of the material being imaged and the probe (attached to the cantilever). Generally, force sensors leverage the relationship between the applied force and the motion of the cantilever, which is given by F = - K*d, where K is a constant and varies with the material type and dimensions of the cantilever.

Working Principle of AFM

A 3D image of a material using AFM is generated by scanning the material with a probe attached to the cantilever. The initial process involved is surface sensing, where the forces between the surface of the material bring the probe closer to the material. However, once the probe touches the surface, it is repelled by repulsive forces.

Subsequently, detection is accomplished by the movement of the laser that shines on the top of the cantilever. With the movement of the cantilever, the direction of the laser changes, which is recorded using position-sensitive photodiodes (PSPD).

Finally, to image the surface, the cantilever scans over the uneven surface of the samples, resulting in the deflection of the laser. Tracking the deflections and adjusting the height of the tip (to maintain the position of the laser) helps attain a 3D map of the sample’s surface.

Limitation of AFM

- The images produced by AFM are limited by the probe material. If the protrusion of the sample surface is narrower than that of the tip, the image produced is inaccurate.

- AFM has a major disadvantage compared with scanning electron microscopy (SEM) in terms of imaging. While SEM can image at the millimeter level in terms of area and depth of the field, AFM can only image up to the micrometer level depth and a maximum area of 150 × 150 µm.

Recent Studies

An article published in Analytical Letters reported the use of AFM to characterize the surface topography and surface roughness of a Ti-3Cu alloy in phosphate-buffered saline (PBS) containing bovine serum albumin (BSA).

AFM imaging revealed the accumulation of serum protein in the semiconducting oxide layer of the Ti-3Cu alloy, suggesting a reduction in the donor site owing to the reconstruction of the oxide film via chemisorption, which in turn was determined by the change in the magnitude of the nano-roughness using AFM.

Another article published in Life reported the influence of surface topography on the initial adhesion of the bacteria Enterococcus faecalis on gutta-percha (GP) cones and plasticized disks of GP using AFM. The results revealed that the GP surface with roughness and waviness resulted in more contamination, suggesting plasticization of GP to reduce surface irregularities, which reduced the retention of bacteria.

Conclusion

Overall, AFM is a robust method for measuring the surface topography of a wide range of materials at a high resolution. The facile operation and lack of sample preparation requirement make AFM a more reliable method than other microscopy methods.

More from AZoOptics: Fluorescence Lifetime Imaging Microscopy for Investigating Molecular Interactions

References and Further Reading

Atomic Force Microscopy . Accessed on (Accessed on 16 September 2023)

Atomic force microscopy for studying surface topology. (Accessed on 16 September 2023). Available at https://www.jeremyjordan.me/atomic-force-microscopy-for-studying-surface-topology/

Atomic Force Microscopy (AFM) - A key tool for nanotechnology. (Accessed on 16 September 2023). Available at https://www.nanowerk.com/spotlight/spotid=4876.php

What Are the Main Components of An AFM System? (Accessed on 16 September 2023) Available at https://www.azooptics.com/Article.aspx?ArticleID=2459

Siddiqui, M. A., Jabeen, A., Chandio, A., Tayyab, S., Yang, K. (2023). Characterization of the Influence of Bovine Serum Albumin (BSA) upon the Electronic Properties and Surface Topography of a Ti-3Cu Biomedical Alloy by Mott-Schottky Analysis (MSA) and Atomic Force Microscopy (AFM). Analytical Letters, 56(10), 1675-1684. https://doi.org/10.1080/00032719.2022.2140163

Ribeiro, A. V., Velásquez-Espedilla, E. G., de Barros, M. C., de Melo Simas, L. L., de Andrade, F. B. (2023). Influence of Gutta-Percha Surface on Enterococcus faecalis Initial Adhesion In Vitro: An Atomic Force Microscopy Study. Life, 13(2), 456. https://doi.org/10.3390/life13020456

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.