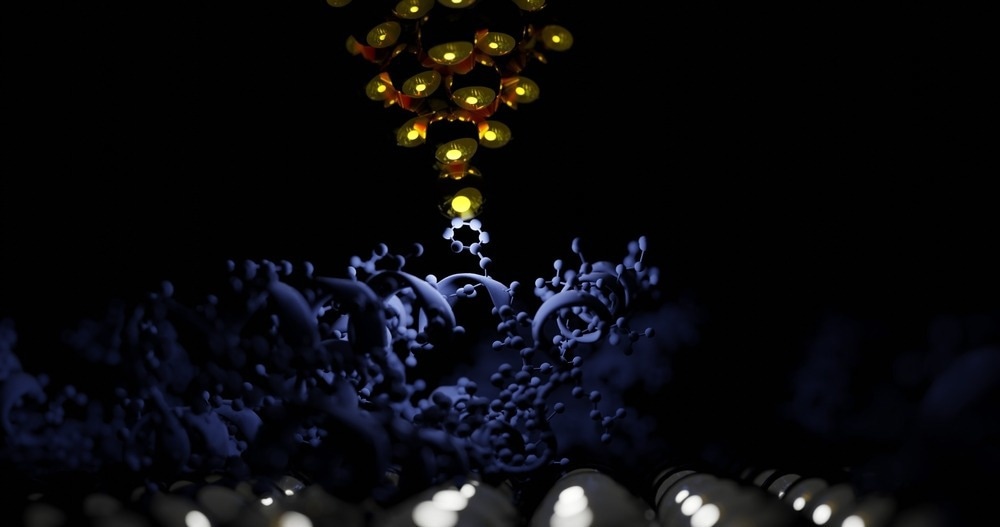

Characterizing the surface topography of materials and devices is vital to determine their mechanical and physical properties. This article will look at the field of surface metrology and how atomic force microscopy (AFM) can benefit the analysis of complex surface features.

Image Credit: sanjaya viraj bandara/Shutterstock.com

What is Surface Metrology?

Recent advances in fields such as nanotechnology, materials science, and semiconductor design have facilitated the development of technologies that can intimately and accurately analyze nano-scaled surface features.

Surface topographies such as patterns, waves, surface roughness, and irregularities can affect critical factors such as friction between components that can lead to wear and reduced service life. Miniscule surface irregularities can increase localized electrical charges.

Surface metrology has become an essential engineering and scientific field. Surface metrology techniques can provide precise, rapid characterization of micro- and sub-microscale surface features.

Fields such as semiconductor design rely on surface metrology to ensure that nanoscale wafer surfaces are smooth and uniform. Minute defects that would otherwise be undetectable can cause critical issues with commercial semiconductors, which are a central technology in many industries.

Surface Metrology Techniques

Several surface metrology techniques are utilized to analyze nanoscale and microscopic surface features on materials and devices. Images of surface features can be captured in both two- and three dimensions. Many techniques are non-destructive, allowing for high-throughput and repeatable analysis.

Contact and non-contact profilometry uses a fine scanning probe to detect surface features. Confocal microscopy, interferometry, optical profilometry, and phase detection use light. SEM is also widely used, though this method is expensive and requires specialized software to display three-dimensional surface topography.

Another common method used in surface metrology is atomic force microscopy (AFM.)

What is AFM?

AFM is another probe imaging method that uses a cantilever and an extremely hard tip. This method provides the operator with high lateral and vertical resolution, but one disadvantage of AFM is its speed at acquiring topographical data. Moreover, this technique requires highly specialized operators.

Another key issue with AFM is the risk of damage and alteration to the surface, which can be deleterious to the manufacturing process as this significantly affects the quality of products. Furthermore, wear and contamination can occur due to changes in the shape and size of the probe during scanning.

Despite its potential drawbacks, AFM is a powerful technique for the analysis of surface features. AFM is routinely employed in the fields of life sciences, semiconductor design, and nanotechnology.

A standalone system is employed to provide topographical data. Modern AFM systems are much faster than those initially developed in the 1980s and can provide surface topography measurements on the angstrom scale (0.1 nm.)

AFM’s Suitability for Surface Metrology

The power of atomic force microscopy for surface metrology comes down to its ability to provide spatial data in all three dimensions. The physical contact between the microscope’s tip and the surface enables accurate quantitative measurements of texture and surface features.

Important metrological measurements are enabled by AFM. These include surface roughness, irregular features, and advanced measurements such as kurtosis and skewness.

Another key advantage of AFM is its flexibility, meaning it can be employed for the analysis of numerous types of surfaces. The technique can be employed without any need for sample preparation except to ensure its physical dimensions can fit into the machine.

AFM can measure surface topography in the contact or “tapping” modes. In the contact mode, the tip is applied to the surface with consistent cantilever deflection, “dragging” it across the sample. In this mode, the load is user-defined and depends on the surface under analysis.

Softer surfaces require a lighter load, whereas stiff and robust materials require a heavier load. Z-axis piezo motion provides surface topography information.

The tapping mode is more dynamic. A resonance frequency is employed to provide tip constant oscillation, causing the tip to interact gently with the surface and providing information on key parameters such as surface roughness.

Using the appropriate mode, an AFM operator can capture information on complex surfaces of biological cells, semiconductors, metals, polymers, and many other types of devices and materials.

When it comes to surface roughness, only methods that can provide quantitative z-measurements can be used to provide data for accurate analysis. Methods that only give a 3D impression without height quantification, such as SEM, are insufficient. AFM is a much more reliable and accurate method for surface metrology.

In Conclusion

Analyzing and categorizing surface roughness and other critical parameters is essential for multiple industries. Accurate data is key to the design of products such as semiconductors and nanomaterials, requiring powerful techniques in the field of surface metrology.

Atomic force microscopy is a method that provides accurate three-dimensional information on surface topography, crucially in the Z axis. Similar technologies, such as optical microscopy and scanning electron microscopy, cannot provide accurate data on the height of surface features, rendering them ineffective for this purpose.

AFM has been around since the 1980s, and today, machines are becoming faster and more sophisticated, providing analysis of surface features in unprecedented detail at the angstrom level. Surface metrology makes extensive use of this effective technique.

More from AZoOptics: How is Electron Microscopy Used for Fiber and Textile Analysis?

References and Further Reading

Oxford Instruments (2023) Semiconductor Atomic Force Microscopy (AFM) [online] afm.oxinst.com. Available at:

https://afm.oxinst.com/outreach/semiconductor-atomic-force-microscopy-afm

Nanosurf (2023) Topography and surface roughness measurements [online] nanosurf.com. Available at:

https://www.nanosurf.com/en/support/afm-modes-overview/topography-and-surface-roughness-measurements

DeRose, J et al. (2019) Brief introduction to surface metrology [online] Leica Microsystems. Available at:

https://www.leica-microsystems.com/science-lab/applied/brief-introduction-to-surface-metrology/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.