Atomic force microscopy (AFM) is an indispensable tool to image and characterize samples in colloidal states such as mineral flotation.

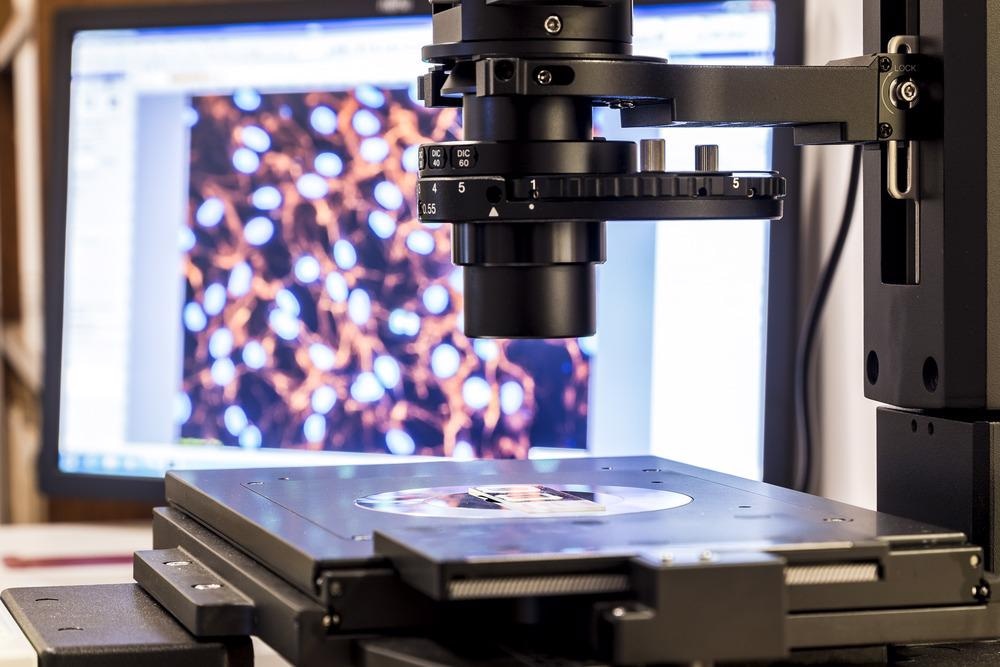

Image Credit: dominika zara/Shutterstock.com

Understanding mineral flotation enables efficient methods for separating and concentrating valuable minerals. High-grade mineral concentrates are used in pyrometallurgical and hydro-metallurgical industries.

Separating Minerals

Froth flotation is the most efficient water-based method for mineral

separation. It is a physical-chemical process based on the difference in surface properties between minerals and other colloidal substances.

Flotation collectors are used as flotation reagents in the separation process. Flotation collectors are chemical substances that modify the surface properties of the minerals. It supports selectively separating particles from colloidal mixtures.

Scientists simulate the flotation purification process into laboratory-scale frothing cells. Here, industrial conditions are reproduced. Selecting appropriate collectors and optimizing satisfactory conditions are crucial to ensuring an effective mineral separation process.

Purity analysis is carried out using AFM, among other methods. AFM images can determine the mineral composition and minor element impurities.

AFM Techniques

AFM is a scanning probe microscopy technique capable of acquiring atomic resolution images.

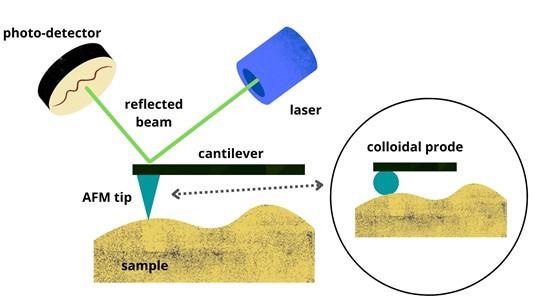

As seen in figure 1, a sharp nanoscale tip is mounted near the end of a cantilever. The cantilever acts as a sensitive spring that compresses and stretches when the probe encounters a force.

The probe is scanned across the surface of the sample under investigation.

The laser and photodetector setup allow optical detection of the cantilever movements, as seen in figure 1.

Images are obtained by a proportional relationship between the spring constant of the cantilever and the associated laser deflection. A complete surface scan can produce high-resolution three-dimensional topographical images.

An innovation of the AFM tip, the colloidal probe technique, allows the imaging of local properties of a colloidal sample, for example, adhesion, stiffness and charge.

In the colloidal probe method, the sharp AFM tip is replaced by a micrometer-sized particle with a well-defined shape (figure 1 inset). The spherical geometry of the colloidal probe makes it more suitable for quantitative analysis.

Figure 1: Schematic illustrations showing basic principles of AFM. Inset - A colloidal probe replaces the sharp AFM tip. Image Credit: Ilamaran Sivarajah

Examples of AFM in Mineral Flotation

AFM allows detailed imaging of mineral surfaces in liquid. High-resolution images of water structures at the solid-water interface provide valuable insights into flotation mechanisms.

Bubble-particle interactions play an essential role in flotation. Bubble-particle attachment depends on the hydrophobic force which is defined as the attractive force between molecules that are not easily soluble in water, and the surfaces that draw them together.

AFM with colloidal probes has been used to study bubble-particle interaction at a nanometer scale directly.

Knowledge of inter-particle forces is significant in colloidal particle separation, particularly the interaction between the mineral surfaces and flotation reagents.

As previously stated, flotation collectors and other kinds of flotation reagents, such as frothers, dispersants, and flocculants, are regularly used to control interfacial properties. AFMs have been successfully demonstrated to capture vital information about inter-particle forces.

Nanobubbles or air can form in hydrophobic surfaces under specific physical conditions and are stable for long periods. Nanobubbles enhance flotation recovery, therefore, understanding the mechanisms behind nanobubbles at the solid-water interface is essential. AFMs were instrumental in experimentally detecting surface nanobubbles for the first time.

Outlook of Using AFM For Mineral Flotation

AFM has been established as a significant instrument in mineral flotation science. It has been used for both imaging and force sensing.

AFMs have successfully resolved mineral flotation, helping to study the adsorption of flotation collectors on mineral surfaces, characterize the water structure at the mineral-water interface, and calibrate inter-particle forces.

AFMs have provided high-resolution details of nanoscale interaction, significantly improving the fundamental knowledge of mineral flotation.

Several drawbacks to advancing imaging precision still exist. The lack of hard contact points restricts imaging shapes of water-air interfaces accurately.

New AFM-based techniques have to be developed to analyze surface morphology and chemical composition. AFM combined with optical spectroscopy analysis is predicted to provide more insights into mineral flotation dynamics.

References and Further Reading

Jupille, Jacques. (2014). Analysis of Mineral Surfaces by Atomic Force Microscopy. Reviews in Mineralogy and Geochemistry. 78. 331-369. https://doi.org/10.2138/rmg.2014.78.8

Xing, Yaowen & Xu, Mengdi & Gui, Xiahui & Cao, Yijun & Babel, Bent & Rudolph, Martin & Weber, Stefan & Kappl, Michael & Butt, Hans-Jürgen. (2018). The application of atomic force microscopy in mineral flotation. Advances in Colloid and Interface Science. 256. https://doi.org/10.1016/j.cis.2018.01.004.

Gao, Ying, Yuexin Han, and Wenbo Li. 2018. "Flotation Behavior of Diatomite and Albite Using Dodecylamine as a Collector" Minerals 8, no. 9: 371. https://doi.org/10.3390/min8090371

Witko, T., Baster, Z., Rajfur, Z. et al. Increasing AFM colloidal probe accuracy by optical tweezers. Sci Rep 11, 509 (2021). https://doi.org/10.1038/s41598-020-79938-z

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.